Call for Price: 0086-15515573212

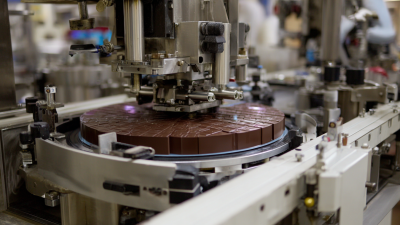

In today's competitive chocolate manufacturing landscape, the selection of an efficient Chocolate Wrapping Machine is pivotal for ensuring product quality and operational efficiency. According to a report by Smithers Pira, the global chocolate market is expected to reach a value of $161.56 billion by 2024, highlighting the critical need for manufacturers to optimize their production processes. The right wrapping machinery not only enhances shelf life and presentation but also significantly impacts throughput and labor costs. With advancements in technology and diverse options available, choosing a wrapping machine tailored to specific needs can enhance productivity and meet consumer demands. This guide aims to demystify the factors to consider when selecting a Chocolate Wrapping Machine, ensuring that your factory remains competitive in an ever-evolving market.

Selecting the right chocolate wrapping machine is crucial for maximizing production efficiency in any chocolate manufacturing facility. According to a recent industry report by Smithers Pira, packaging efficiency can influence overall production costs by up to 20%. A well-chosen wrapping machine not only improves the speed of the packaging process but also enhances the aesthetic presentation of the product, which can significantly impact market appeal. With the right machine, factories can ensure that their chocolates are packaged securely and attractively, minimizing waste and preserving quality.

Selecting the right chocolate wrapping machine is crucial for maximizing production efficiency in any chocolate manufacturing facility. According to a recent industry report by Smithers Pira, packaging efficiency can influence overall production costs by up to 20%. A well-chosen wrapping machine not only improves the speed of the packaging process but also enhances the aesthetic presentation of the product, which can significantly impact market appeal. With the right machine, factories can ensure that their chocolates are packaged securely and attractively, minimizing waste and preserving quality.

When evaluating equipment, consider investing in machines that offer versatility in wrapping styles and materials. Modern machines come with features that accommodate various products, whether they are bars, truffles, or pralines. Such adaptability ensures that manufacturers can respond quickly to changing market demands without overhauling their entire production line.

Tips: Always prioritize machines with advanced automation capabilities that integrate seamlessly with existing production lines. Regular maintenance schedules are essential to minimize downtime, ensuring consistent production flows. Additionally, factor in the machine's energy efficiency; according to a survey by the food packaging industry, energy-efficient machines can reduce operational costs by up to 15%.

When selecting the best chocolate wrapping machine for your factory, it's crucial to consider several key features to ensure optimal performance and efficiency. One of the top features to look for is the machine's wrapping speed. A fast wrapping machine can significantly boost your production line by reducing bottlenecks, so assess your production capacity and choose a machine that meets your output needs.

Another essential consideration is versatility. A machine that can accommodate various types of chocolate products—such as bars, truffles, or seasonal shapes—can greatly enhance your packaging flexibility. This adaptability not only helps in catering to different market demands but also saves you from investing in multiple machines.

Additionally, ease of use and maintenance should be at the forefront of your decision-making process. A user-friendly interface can simplify the setup and operation for your staff, while a machine designed for easy cleaning and maintenance will minimize downtime. Implementing regular maintenance checks will prolong the machine's lifespan and ensure it operates at peak efficiency. By focusing on these features, you can invest in a wrapping machine that will effectively support your chocolate production goals.

When selecting the best chocolate wrapping machine for your factory, evaluating industry data is crucial to ensure optimal packaging solutions. Recent reports indicate that the global chocolate packaging market is projected to reach $48 billion by 2025, growing at a CAGR of 4.7%. This growth underlines the importance of efficiency and technology in packaging. Key metrics to consider include production speed, machine durability, and compatibility with various chocolate types. Understanding these metrics can profoundly impact your manufacturing process, ensuring that your operations remain competitive and cost-effective.

**Tip 1:** Invest in machines that offer versatility. A wrapping machine that can handle multiple types of chocolate, from bars to truffles, can save you from costly retools.

**Tip 2:** Look for energy-efficient models. According to the Packaging Machinery Manufacturers Institute, energy-efficient machines can reduce consumption by up to 30%, translating into significant cost savings over time.

By focusing on these key metrics and industry insights, you can make a well-informed decision that enhances your factory's production capabilities and aligns with market trends.

| Metric | Value | Unit | Best Practice |

|---|---|---|---|

| Production Speed | 150 | units/min | Opt for high-speed machines for larger output. |

| Wrap Type Compatibility | 3 | types | Select machines that handle multiple wrap types (e.g., foil, plastic, paper). |

| Changeover Time | 5 | minutes | Choose machines with quick changeover features to minimize downtime. |

| Machine Size | 2.5 | m x 1.5 m x 1.8 m | Ensure adequate space in your factory for installation. |

| Energy Consumption | 2.5 | kWh | Consider energy-efficient models to reduce operational costs. |

| Maintenance Frequency | Monthly | - | Regular maintenance ensures optimal performance and longevity. |

| Warranty Period | 2 | years | Look for extended warranty options for added security. |

When considering the investment in a chocolate wrapping machine for your factory, a thorough cost-benefit analysis is essential. This analysis begins with understanding the initial purchase cost of the machine, which can vary greatly depending on features, automation level, and brand. It's crucial to factor in not only the upfront cost but also the long-term operational expenses, including maintenance, energy consumption, and potential training for staff. Recognizing these costs helps in establishing a clear financial picture.

In addition to the initial and operating costs, the benefits of using a high-quality chocolate wrapping machine should not be underestimated. These machines can significantly boost production efficiency, reduce labor costs, and enhance packaging quality. Improved packaging not only extends the shelf life of products but also increases consumer appeal, potentially driving higher sales. Therefore, by systematically evaluating both the costs and benefits, your factory can make an informed decision that aligns with long-term profitability and operational success.

In the dynamic realm of the food industry,

packaging innovation has emerged as a critical trend. It plays a pivotal role in

maintaining food quality, ensuring safety, and extending shelf life. Recent

advancements in chocolate wrapping technology are poised to reshape production

processes and enhance efficiency. According to market research, the global

chocolate market is projected to grow from

$148.75 billion in 2025

to $221.11 billion by

2033, with a CAGR of 5.08%. This growth underscores

the significant opportunity for innovative packaging solutions to impact overall

production.

Furthermore, the chocolate and confectionery processing equipment market is

also expected to see substantial growth. Reports indicate that the demand for

packaging machines is on the rise due to a shift towards automation and higher

production capacities. Swiss food tech companies

are at the forefront of this transformation, developing plant-based cell culture

technologies that facilitate the rapid creation of new product lines, including

alternatives to traditional cocoa products. As the industry embraces these

innovations, the focus on sustainable and

attractive packaging will be crucial in capturing consumer attention and driving

market expansion.