Call for Price: 0086-15515573212

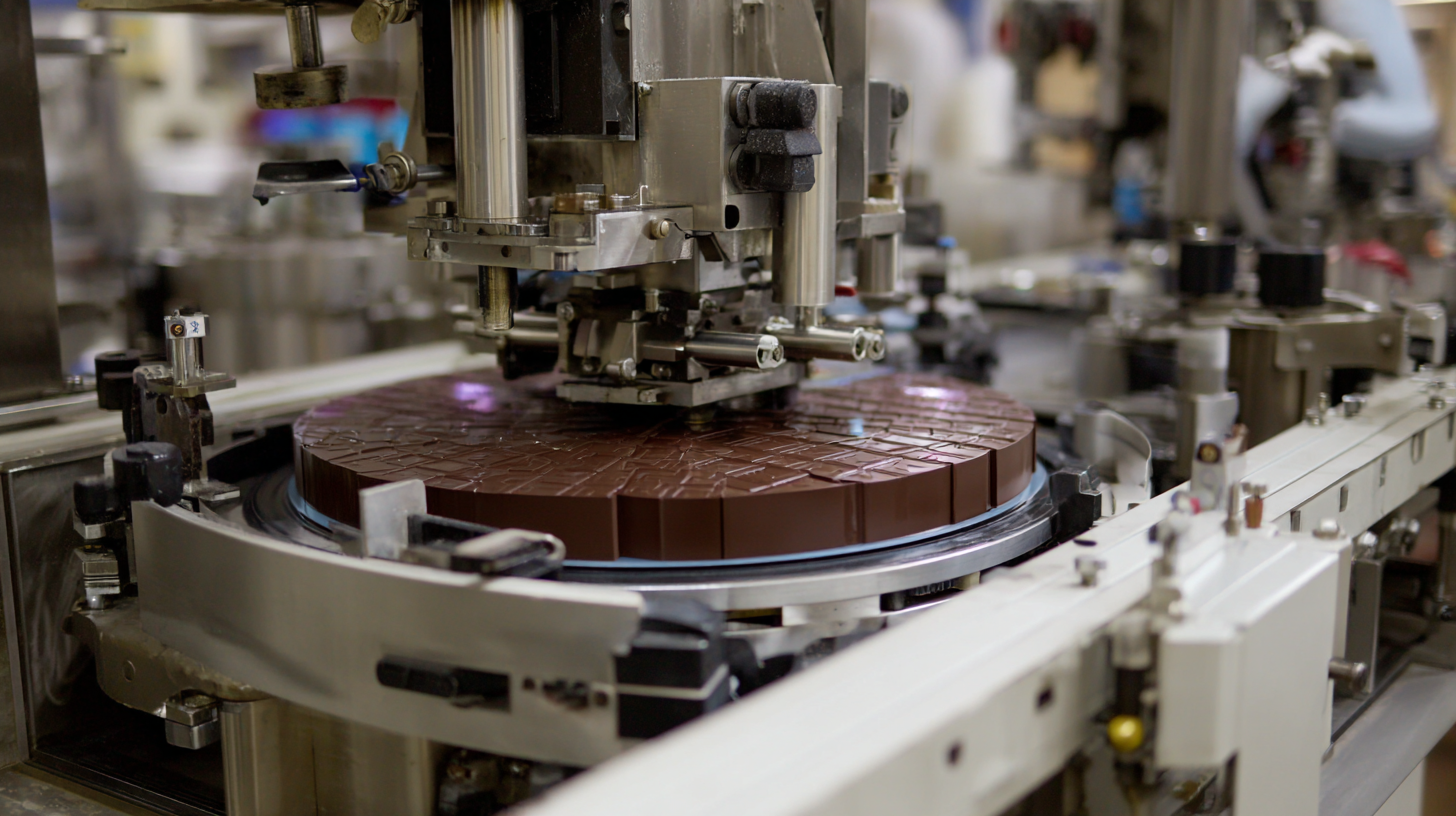

In today's fast-paced world, mastering efficiency in production is crucial, especially in the confectionery industry. A key component of streamlining operations is selecting the right machinery, with the Chocolate Wrapping Machine standing out as a vital investment for chocolatiers. This machine not only enhances the visual appeal of the packaged products but also ensures optimal freshness and quality. However, with numerous available options, choosing the best Chocolate Wrapping Machine can be a daunting task.

This guide will navigate you through the essential factors to consider, including speed, versatility, and cost-effectiveness, while providing concrete examples to illustrate how the right machine can elevate your packaging process. Join us as we delve into a step-by-step approach to help you make an informed decision that aligns with your business needs and enhances overall efficiency.

When it comes to chocolate production, the wrapping process is as crucial as the manufacturing phase. A quality chocolate wrapping machine not only preserves the freshness and flavor of the chocolates but also enhances their visual appeal. Packaging plays a fundamental role in branding and consumer perception; therefore, investing in the right wrapping equipment can significantly affect a company’s success in a competitive market.

When selecting the best chocolate wrapping machine, several key features should guide your decision-making process. Firstly, consider the machine's speed and efficiency. A higher output rate is essential for large-scale production, ensuring that you can meet demand without compromising on quality. Look for machines that offer adjustable speeds to accommodate different product types and packaging styles, allowing for greater versatility in your production line.

Another critical feature to evaluate is the machine's adaptability to various wrapping materials. The ability to work with different types of foil, cellophane, or paper not only broadens your packaging options but also enhances your brand's presentation.

Choosing the right chocolate wrapping machine is essential for optimizing efficiency in your production line. As the global premium chocolate market anticipates significant growth, investing in the right wrapping technology is crucial. Different types of chocolate wrapping machines cater to various needs, from small-scale artisanal operations to large industrial plants. Each machine offers distinct features that enhance packaging speed, quality, and sustainability.

Tip 1: When comparing machines, consider their speed and versatility. Look for models that can handle different chocolate shapes and sizes without compromising on packaging quality. This adaptability can set your production apart in an increasingly competitive market.

Tip 2: Sustainability is a growing concern among consumers and manufacturers alike. Evaluate machines that use eco-friendly materials or have low waste production processes, ensuring your packaging aligns with current market trends towards organic and premium products. This aligns with the increasing consumer demand for environmentally responsible practices in the chocolate industry.

With advancements in technology, new models are being introduced, such as modular systems that offer flexibility and enhanced performance. Staying informed about these innovations can help you make a strategic investment that will boost your efficiency and product appeal.

When considering the purchase of a chocolate wrapping machine, it's crucial to evaluate your production needs meticulously. According to a report by Research and Markets, the global chocolate market is projected to reach USD 161.56 billion by 2024, which underscores the importance of optimizing production efficiency. Understanding your output requirements—be it volume, speed, or specific packaging styles—can significantly influence your machine choice and ultimately your success in this competitive marketplace.

**Tip 1:** Assess your production capacity. Start by analyzing your current output and forecasted demand. If you're planning to scale up, investing in a machine with higher throughput capabilities may be necessary to meet future needs without compromising quality.

**Tip 2:** Evaluate the types of chocolate products you offer. Different products may require distinct wrapping techniques; for instance, pralines may need more delicate handling compared to bar chocolates. This consideration will guide you in choosing a machine that can accommodate the variety of products you plan to package.

By focusing on these areas, businesses can make informed decisions that will enhance efficiency and support productivity in the fast-evolving chocolate industry.

This chart displays the efficiency of different chocolate wrapping machines in terms of units produced per hour. Assessing such data can help in making informed decisions when selecting a machine that meets production needs.

To ensure optimal efficiency of your chocolate wrapping machine, regular maintenance is essential. This not only prolongs the lifespan of the machine but also enhances the quality of the final product. Start with a daily check of the machine’s components, such as belts, rollers, and sensors. Look for any signs of wear and tear, and clean any chocolate residue or debris that may affect the machine's performance. Regular lubrication of moving parts is crucial to minimize friction and prevent overheating.

In addition to daily maintenance, a more comprehensive weekly and monthly schedule should be implemented. This could include inspecting the electrical connections, adjusting tension on belts, and calibrating the wrapping mechanisms. Keep an eye on the alignment of the machine to ensure that wrappers are being placed accurately. Documenting maintenance activities can help identify patterns or recurring issues, enabling proactive measures and reducing unexpected downtime. By dedicating time to maintain your wrapping machine, you not only safeguard your investment but also maintain the high standards of your chocolate production.

| Feature | Importance | Maintenance Tips | Expected Lifespan |

|---|---|---|---|

| Speed of Operation | High | Regularly clean the feeding and sealing areas. | 10-15 years |

| Compatibility with Packaging Materials | Medium | Test with various materials to ensure proper functioning. | 8-12 years |

| Ease of Use | High | Provide training for all operators to minimize errors. | 12-15 years |

| Energy Efficiency | High | Schedule regular audits of energy consumption. | 10-20 years |

| After-sales Support | Medium | Maintain contact with the supplier for spare parts. | Variable |