Call for Price: 0086-15515573212

In today's fast-paced market, efficient and effective packaging solutions are essential for businesses aiming to stand out and maintain a competitive edge. One of the most crucial tools in achieving this goal is the Product Wrapping Machine. This innovative equipment not only enhances the visual appeal of products but also ensures their protection during storage and transportation. As companies strive to meet growing consumer demands while optimizing their operational processes, investing in a Product Wrapping Machine can prove to be a game-changer.

With increasing focus on sustainability and cost-effectiveness, a Product Wrapping Machine offers numerous advantages that can streamline packaging operations. It reduces labor costs, minimizes packaging material waste, and improves the overall consistency of product presentation. Furthermore, the ability to customize packaging styles and materials enables businesses to align their branding strategies effectively, making an impactful statement in the marketplace. Thus, understanding the necessity of a Product Wrapping Machine is paramount for any business looking to enhance its packaging capabilities and ensure long-term success.

The use of a product wrapping machine in packaging brings numerous advantages that can significantly enhance operational efficiency and product protection. One of the primary benefits is consistency in packaging quality. Automated wrapping machines ensure that each item is wrapped uniformly, reducing the risk of human error that often leads to loose or poorly wrapped products. This consistency not only improves the aesthetic appeal of products but also strengthens brand image by projecting professionalism and attention to detail.

Moreover, product wrapping machines improve packaging speed and productivity. In industries where time is of the essence, these machines can wrap large volumes of items in a fraction of the time it would take manual labor. This increased efficiency allows businesses to meet higher demands and maximize output without compromising on quality. Furthermore, with advanced features like adjustable wrapping speeds and various wrapping materials, these machines offer versatility for different products, making them an invaluable investment for any packaging operation.

When it comes to optimizing your packaging processes, understanding the various types of product wrapping machines available is essential. The global packaging machinery market is projected to reach USD 50 billion by 2026, as reported by industry analysts, highlighting the increasing demand for efficient packaging solutions. There are several types of product wrapping machines, each designed to meet specific needs such as speed, flexibility, and material compatibility.

One prominent type is the shrink wrapping machine, which uses heat to tightly cover products with plastic film. This method not only protects items from moisture and contamination but also enhances visual appeal. According to a report by MarketsandMarkets, the shrink wrapping segment is expected to grow at a significant rate, driven largely by the food and beverage industry’s need for safe packaging solutions.

Another common option is the stretch wrapping machine, ideal for securing large or bulky items on pallets. Stretch wrapping is known for its ability to reduce waste and improve load stability, making it an excellent choice for companies focused on sustainability and efficiency.

In addition, there are automated wrapping machines that significantly speed up production lines and reduce labor costs, addressing the increasing pressure for rapid fulfillment in today's fast-paced market. Given that automated solutions are set to dominate the market, with estimates suggesting over 25% of wrapping machines sold in 2025 will be automated, companies that invest in these technologies stand to gain a competitive edge. Understanding these options allows businesses to make informed decisions that align with their packaging needs, ultimately driving operational efficiency and overall effectiveness in their supply chain.

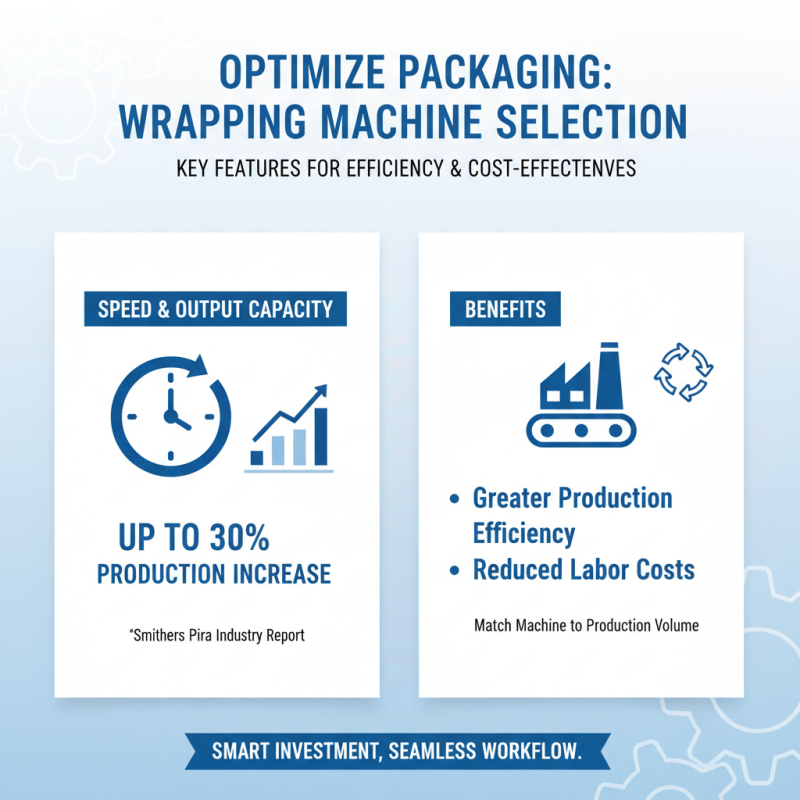

When selecting a wrapping machine for your packaging needs, there are several key features to consider that can significantly impact efficiency and cost-effectiveness. One major aspect is the machine's speed and output capacity. According to a recent industry report by Smithers Pira, manufacturers that invest in high-speed wrapping technology can achieve output increases of up to 30%, allowing for greater production efficiency and reduced labor costs. Choosing a machine that aligns with your production volume is crucial to maintaining a seamless workflow.

Another important consideration is the versatility of the wrapping machine. Options such as adjustable wrapping tension and various film types can enhance packaging quality and protect products effectively. A survey conducted by Packaging Strategies revealed that 68% of companies emphasized the importance of flexibility in their packaging operations, highlighting a trend toward machines that can accommodate a variety of products and packaging materials. This adaptability not only improves packaging lines but also caters to diverse customer needs.

Tips to remember when selecting a wrapping machine include evaluating the total cost of ownership, which encompasses not just the initial purchase price but also maintenance and operating expenses. Always consult with reputable suppliers to gather insights on the latest technology and innovations in the market. Additionally, performing a trial run can help ensure the machine meets specific requirements before committing to a purchase.

In the competitive landscape of manufacturing and distribution, businesses are increasingly recognizing the cost-effectiveness of automated wrapping solutions compared to traditional manual processes. According to a report by Smithers Pira, the flexible packaging market is expected to grow to approximately $300 billion by 2025, driven in part by the efficiencies provided by automation. Automated wrapping machines can significantly reduce labor costs, as they streamline the wrapping process and minimize the need for extensive manual handling, which can lead to considerable savings over time.

Moreover, automated wrapping technologies enhance operational efficiency, with many machines capable of wrapping products at speeds of up to 120 packs per minute. This not only accelerates the production line but also decreases the likelihood of human error, which can lead to product damage and increased waste. Research from the Association for Packaging and Processing Technologies indicates that businesses adopting automation can see up to a 20% reduction in packaging cycle times, enabling them to meet higher consumer demands with greater agility. As a result, the initial investment in a product wrapping machine can be recouped quickly through savings on labor, reduced waste, and improved throughput.

| Packaging Method | Average Cost per Unit | Time Required per Unit (seconds) | Labor Requirements | Error Rate (%) |

|---|---|---|---|---|

| Automated Wrapping | $0.15 | 5 | Minimal (1 Operator) | 1 |

| Manual Wrapping | $0.30 | 15 | 3 Workers | 5 |

| Semi-Automated Wrapping | $0.20 | 10 | 2 Workers | 3 |

In today's competitive market, ensuring product safety and longevity is crucial for businesses aiming to maintain quality and consumer trust. A product wrapping machine plays a significant role in enhancing product shelf life by providing a protective barrier against environmental factors. This barrier minimizes exposure to moisture, oxygen, and light, which can lead to degradation over time. By using advanced materials and technologies, wrapping machines can create a tight seal, preserving the freshness and integrity of products, especially perishable items like food and pharmaceuticals.

Moreover, the safety aspect of packaging cannot be overlooked. A wrapping machine not only safeguards the product from external contaminants but also helps in preventing tampering and damage during transportation. This is especially important in today's supply chain, where products may be subjected to varying conditions. By adopting a reliable wrapping machine for their packaging needs, businesses can ensure that their products arrive at their destination in optimal condition, thereby enhancing consumer confidence and satisfaction.

Ultimately, the investment in a wrapping machine translates into improved product quality and reduced waste, making it an essential asset for any packaging operation.