Call for Price: 0086-15515573212

In today's fast-paced manufacturing and packaging environments, the efficiency of production processes is critical to maintaining a competitive edge. A key component in optimizing this efficiency is the Film Wrapping Machine, which has become indispensable across various industries. According to a report by Smithers Pira, the global packaging machinery market is projected to reach $45 billion by 2025, with a significant portion driven by advancements in automation and technology in wrapping solutions. As companies look to enhance throughput and reduce labor costs, Film Wrapping Machines are leading the charge, offering rapid and reliable packaging solutions that improve product shelf life and reduce waste. This blog will explore comparison strategies for maximizing efficiency with Film Wrapping Machines, delving into best practices and innovations that drive performance, ensuring that businesses can not only meet but exceed the ever-growing demands of the market.

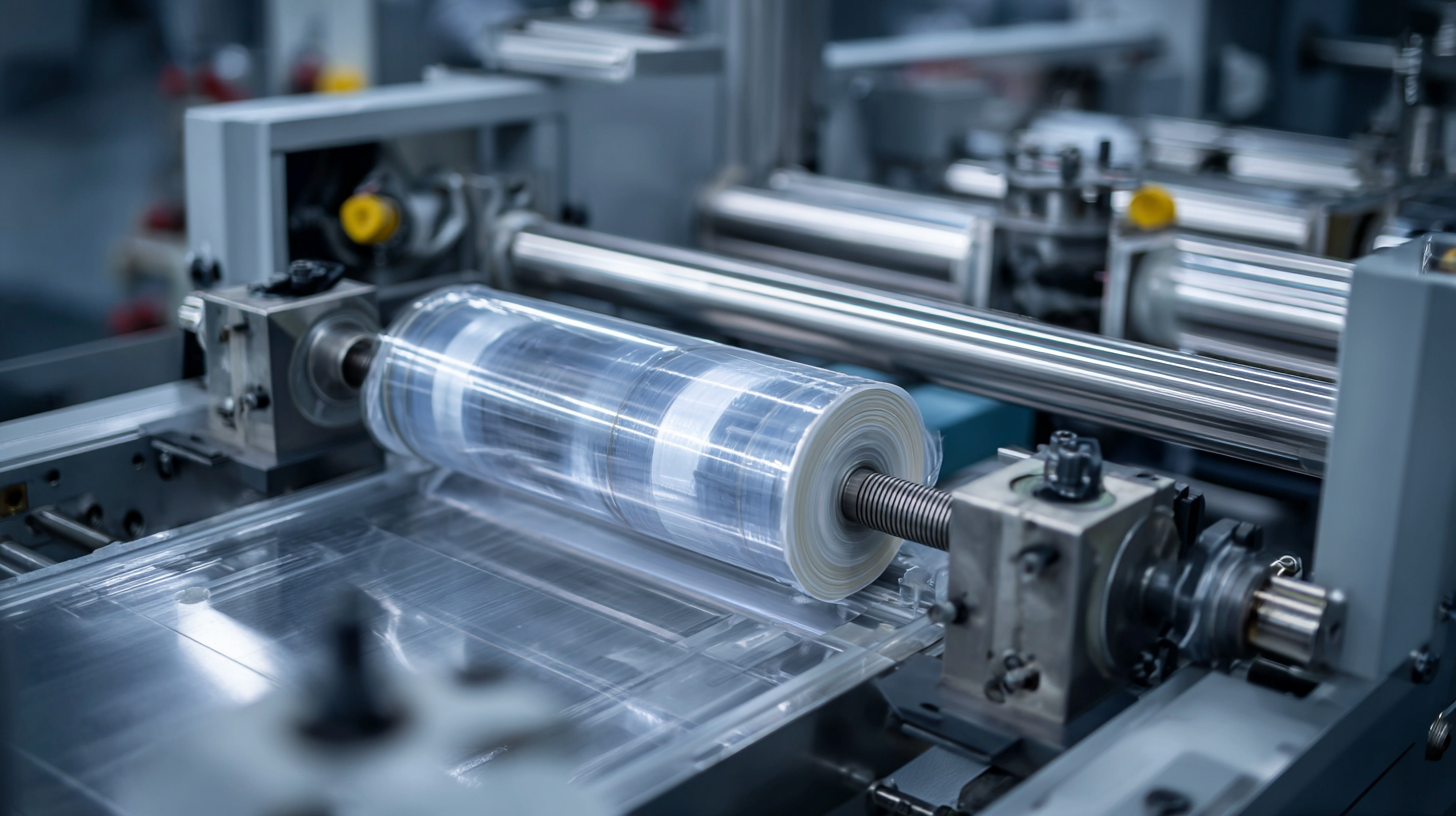

Film wrapping machines are essential tools in modern packaging, greatly enhancing efficiency across various industries. Understanding their key benefits and features can help businesses leverage these machines effectively. One of the primary advantages of film wrapping machines is their ability to provide consistent and reliable packaging solutions. This consistency ensures that products are securely wrapped, minimizing damage during transportation and storage, which is crucial in maintaining supply chain integrity.

Film wrapping machines are essential tools in modern packaging, greatly enhancing efficiency across various industries. Understanding their key benefits and features can help businesses leverage these machines effectively. One of the primary advantages of film wrapping machines is their ability to provide consistent and reliable packaging solutions. This consistency ensures that products are securely wrapped, minimizing damage during transportation and storage, which is crucial in maintaining supply chain integrity.

Additionally, the automation capabilities of film wrapping machines significantly reduce labor costs and improve production speed. By streamlining the wrapping process, operators can focus on other critical tasks, ultimately increasing overall productivity. Features such as adjustable speed and wrap tension can be tailored to suit different products, ensuring flexibility in operations. As industries continue to seek innovative solutions for maximizing efficiency, understanding the functionalities and benefits of film wrapping machines becomes vital in achieving operational excellence.

Automated film wrapping has revolutionized packaging across various industries, offering significant advantages over manual methods. One of the top reasons to choose automated film wrapping is efficiency. These machines streamline the packaging process, reducing labor costs and minimizing material waste. As industries evolve and the demand for higher productivity grows, integrating automated film wrapping can enhance your operation's overall output.

Another reason to consider automated film wrapping is consistency. Unlike manual wrapping, which can lead to variations in package integrity, machines deliver uniform results every time. This consistency helps maintain quality control and improves customer satisfaction. Additionally, automated systems can accommodate diverse product shapes and sizes, making them adaptable to your packaging needs.

Tips for maximizing efficiency with film wrapping machines include regular maintenance to ensure optimal performance, training staff to operate the machines effectively, and utilizing high-quality wrapping materials to enhance durability. By focusing on these strategies, businesses can leverage automated film wrapping systems to achieve significant operational improvements and stay competitive in a rapidly growing market. In the industrial heat transfer equipment landscape, the growing demand emphasizes the importance of efficiency and reliability in packaging solutions.

This bar chart illustrates the top five reasons to choose automated film wrapping for your packaging needs, showcasing their impact on efficiency and productivity.

Maximizing productivity in film wrapping processes requires an in-depth understanding of both the machinery and the materials involved. One of the first steps to optimizing efficiency is ensuring that the film wrapping machine is properly calibrated for the specific type of product being wrapped. This includes adjusting tension settings and speed configurations based on the size and weight of the items. By investing time in initial setup, companies can prevent delays and ensure a smoother workflow, ultimately reducing downtime and increasing output.

Additionally, regular maintenance of the wrapping machines plays a critical role in sustaining productivity levels. Frequent checks on the equipment can identify potential issues before they escalate, therefore avoiding unexpected breakdowns that could halt production. Furthermore, training staff on best practices for operating the machines not only streamlines the wrapping process but also empowers employees to troubleshoot minor issues independently, enhancing overall efficiency. Incorporating performance metrics can provide insights into where improvements can be made, allowing for data-driven decisions that refine operations further.

Maintaining film wrapping machines is crucial for ensuring their longevity and optimal performance. Regular inspection and cleaning are necessary to prevent dirt and debris from impairing the machinery. Check for any wear and tear on critical components, such as the film carriage and cutting blade. A simple cleaning routine that includes wiping down surfaces and clearing any obstructions can enhance machine efficiency significantly. Additionally, lubricating moving parts according to the manufacturer's recommendations can help minimize friction and reduce the risk of malfunction.

Another essential maintenance strategy involves monitoring the wrapping process for consistency and accuracy. This includes calibrating the machine settings regularly to align with the specific requirements of the materials being used. Ensuring that the film is loaded correctly and that the tension is optimal can prevent unnecessary strain on the machine. Moreover, scheduling routine professional maintenance checks can identify potential issues before they become significant problems, allowing for timely repairs and adjustments. By adhering to these maintenance tips, operators can ensure that their film wrapping machines remain efficient and reliable over time.

| Strategy/Maintenance Tip | Description | Frequency | Impact on Efficiency |

|---|---|---|---|

| Regular Cleaning | Remove dust, debris, and residues to maintain machine performance. | Daily | High |

| Lubrication | Ensure moving parts are adequately lubricated to reduce friction. | Weekly | Medium |

| Film Quality Check | Inspect film for defects before use to avoid wrapping failures. | Every Batch | High |

| Calibration | Regularly calibrate settings for consistent wrapping tension. | Monthly | Very High |

| Parts Inspection | Check for wear and tear on essential components. | Quarterly | High |

In the fast-paced world of packaging, film wrapping machines play a pivotal role in enhancing operational efficiency. Innovative technologies have emerged that significantly improve the performance of these machines, making them essential tools for businesses aiming to streamline their processes. One notable advancement is the integration of IoT (Internet of Things) capabilities, allowing for real-time monitoring and data collection. This enables operators to track machine performance, identify bottlenecks, and make informed decisions that optimize workflow.

Another groundbreaking technology is the adoption of advanced sensor systems. These sensors can detect film thickness, tension, and wrapping speed, ensuring consistent quality across production runs. By automating adjustments based on sensor feedback, film wrapping machines not only reduce material waste but also guarantee better protection for the packaged products. Furthermore, the implementation of AI-driven algorithms can forecast maintenance needs, virtually eliminating unexpected downtime and enhancing the overall efficiency of wrapping operations. As these innovative technologies continue to evolve, they are setting new benchmarks for efficiency and productivity in the packaging industry.