Call for Price: 0086-15515573212

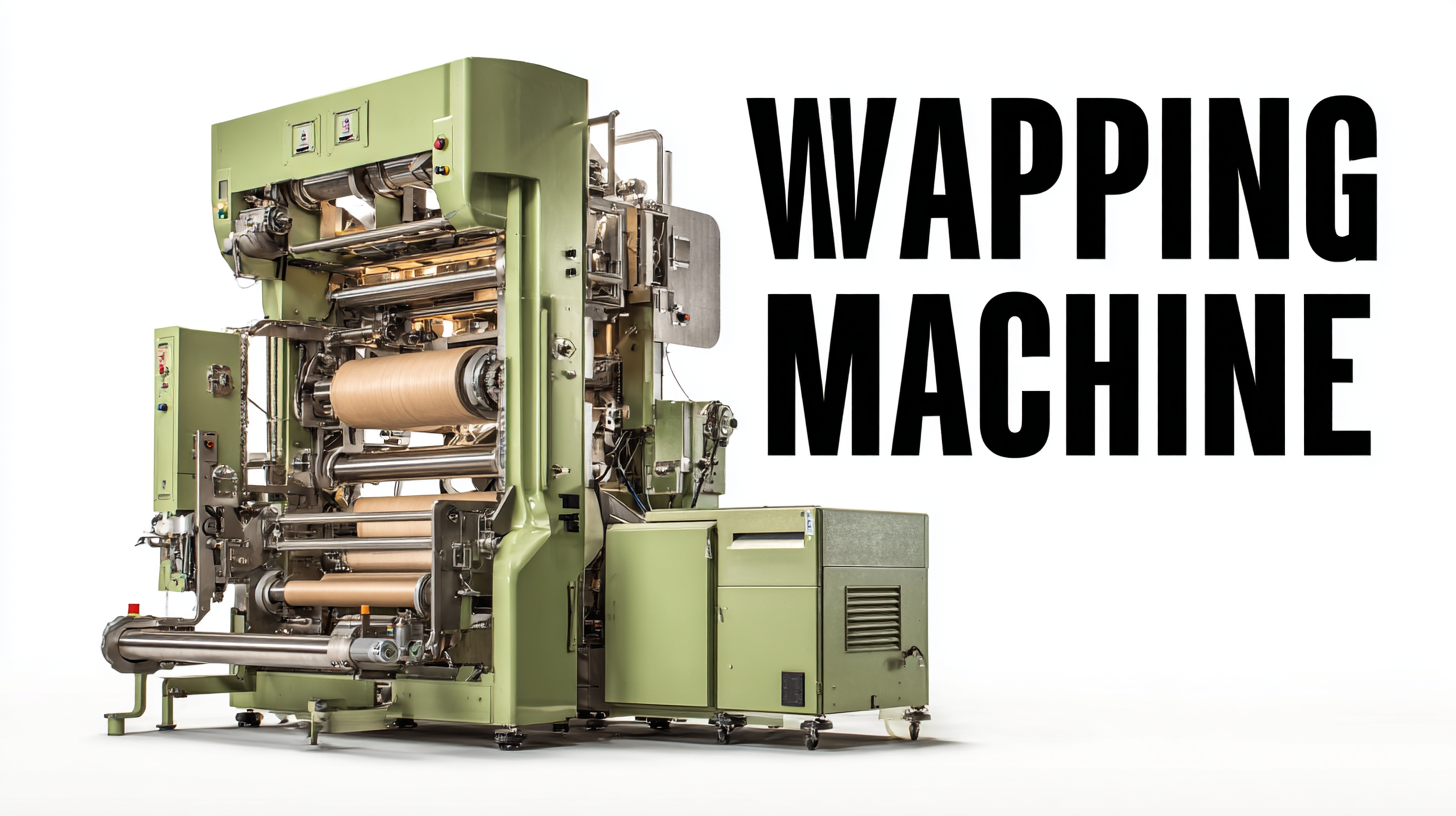

The wrapping machine is an essential tool in various industries, revolutionizing packaging processes with enhanced efficiency and precision. According to a recent industry report by Grand View Research, the global packaging machinery market is expected to reach USD 51.11 billion by 2025, highlighting a significant demand for advanced wrapping machines across sectors such as food and beverage, pharmaceuticals, and e-commerce. These machines not only improve product shelf life and safety but also play a crucial role in reducing packaging waste and labor costs.

Innovative applications of wrapping machines are continually emerging, demonstrating their versatility and adaptability in meeting diverse industry needs. From ensuring hygiene in healthcare products to optimizing logistics in retail, the impact of wrapping machines is profound, underscoring their importance in modern manufacturing and distribution strategies.

In the competitive landscape of wrapping machine industries, the significance of after-sales service cannot be overstated. When businesses invest in wrapping machinery, they gain not only a physical asset but also the peace of mind that comes with knowing they have a partner in operational efficiency. Robust after-sales support ensures that any issues that arise are addressed promptly, minimizing downtime and enhancing productivity. Companies that prioritize after-sales service often enjoy improved customer loyalty and repeat business, as clients recognize the added value of ongoing support.

Moreover, effective after-sales service can prevent small problems from escalating into major setbacks. Regular maintenance, timely upgrades, and staff training provided by manufacturers help clients maximize the functionality of their wrapping machines. This proactive approach not only extends the lifespan of the equipment but also optimizes performance, making it a wise investment for businesses across various industries. In essence, when companies choose wrapping machinery, they should also consider the caliber of after-sales service, as it can significantly influence their operational success and long-term satisfaction.

| Industry | Example Application | Wrapping Technique | Benefits of After-Sales Service |

|---|---|---|---|

| Food & Beverage | Wrapping snack items | Shrink Wrapping | Quick response to equipment issues |

| Cosmetics | Packaging lotions and creams | Flow Wrapping | Regular maintenance checks |

| Pharmaceuticals | Wrapping tablets and capsules | Blister Packaging | Training for operational efficiency |

| Electronics | Securing components in bulk | Stretch Wrapping | 24/7 customer support |

| Textiles | Wrapping fabric rolls | Banding | Flexible service agreements |

In today's fast-paced commercial landscape, businesses are discovering that the cost-effectiveness of maintenance for various packing solutions can significantly impact their bottom line. According to a recent report from the Packaging Machinery Manufacturers Institute (PMMI), companies investing in automated wrapping machines experience a reduction of up to 20% in labor costs, which directly correlates with decreased maintenance needs. The systematic upkeep of these machines enhances operational efficiency, reducing the frequency of breakdowns and unscheduled downtime.

Tips: Regular maintenance schedules not only prolong the lifespan of wrapping machines but also ensure optimal performance. Simple steps, such as routine cleaning and inspections, can prevent small issues from escalating into costly repairs.

Moreover, businesses that opt for the latest wrapping machine technology often enjoy enhanced packing speed and material utilization. A study by the Association for Packaging and Processing Technologies revealed that improving machine efficiency can lead to a 15% reduction in material waste, translating into significant savings over time. Companies reaping these benefits find their investment pays off quickly, particularly when integrating innovative technologies that simplify maintenance tasks.

Moreover, businesses that opt for the latest wrapping machine technology often enjoy enhanced packing speed and material utilization. A study by the Association for Packaging and Processing Technologies revealed that improving machine efficiency can lead to a 15% reduction in material waste, translating into significant savings over time. Companies reaping these benefits find their investment pays off quickly, particularly when integrating innovative technologies that simplify maintenance tasks.

Tips: Training staff on the specific functionalities of advanced wrapping machines can optimize their use, minimize errors, and reduce wear and tear, ultimately saving on maintenance costs.

The wrapping machine technology is evolving rapidly, driven by advancements in automation and material science. Future trends indicate a significant shift towards more intelligent machines equipped with artificial intelligence and machine learning capabilities. These innovations will enhance the efficiency of wrapping processes, allowing businesses to adapt to varying product sizes and shapes with ease. As these machines become smarter, they can also integrate with other systems within a production line, enabling real-time data collection and analysis for optimal performance.

Tip: When considering a wrapping machine for your business, look for models with adjustable settings to accommodate a variety of products. This flexibility can help you save costs and reduce downtime, ultimately increasing your productivity.

Additionally, sustainability is set to become a cornerstone of wrapping machine design. Manufacturers are increasingly focused on producing machines that utilize eco-friendly materials and minimize waste. Trends such as biodegradable wrapping films and energy-efficient machines are gaining traction, reflecting a growing commitment to protecting the environment.

Tip: Invest in wrapping machines that support renewable materials or offer recyclable packaging options, as this can enhance your brand's image and attract eco-conscious consumers.

This chart illustrates the distribution of wrapping machine usage across various industries in 2023. It highlights the growing adoption of wrapping machines in food, pharmaceuticals, electronics, and consumer goods, reflecting the trends in technology and innovation.

The impact of automation on packaging processes has transformed various industries, enhancing efficiency and reducing operational costs. According to a report by the The Freedonia Group, the global market for packaging automation is expected to grow by 7.5% annually, reaching over $70 billion by 2025. This surge is largely driven by the increasing demand for high-speed packaging solutions that can adapt to different product types and sizes. Automated wrapping machines are at the forefront, offering precise and consistent packaging, which is essential in sectors such as food and beverage, pharmaceuticals, and consumer goods.

In the food industry, companies like Nestlé have reported significant improvements in productivity due to automated wrapping systems. Their adoption of advanced machinery has led to a 15% increase in packaging speed and a reduction in material waste by up to 20%. Similarly, in the pharmaceutical sector, the push for compliance with stringent regulations means that automating the packaging processes not only aids in efficiency but also enhances traceability and safety. A study from the Pharmaceutical Packaging Association highlighted that automation could potentially save the industry over $1 billion annually through fewer errors and faster throughput, underscoring the critical role of innovative wrapping machines in modern packaging landscapes.

In recent years, sustainability has become a critical focus for industries utilizing wrapping machines, as evidenced by a report from Smithers Pira, which highlights that the global demand for sustainable packaging solutions is expected to grow by 7.4% annually until 2024. Many manufacturers are integrating eco-friendly practices into their wrapping processes, such as using biodegradable materials and energy-efficient machines. For instance, companies like Sealed Air have pioneered the use of recyclable films in their packaging solutions, reducing plastic waste and carbon footprints while maintaining product safety and integrity.

Moreover, advancements in wrapping machine technology have significantly contributed to sustainability efforts. A study by the Packaging Association indicates that modern wrapping machines can reduce material usage by up to 20%, thereby lowering overall waste. These machines often feature intelligent automation and optimization capabilities that minimize excess packaging while enhancing efficiency. Consequently, not only do businesses meet environmental standards, but they also benefit from cost savings and increased productivity. As industries continue to prioritize sustainable practices, the role of innovative wrapping machines becomes indispensable in helping them achieve their eco-friendly goals.