Call for Price: 0086-15515573212

As the landscape of manufacturing continues to evolve, the significance of automation in the realm of packing machines has never been more pronounced. Recent industry reports indicate that the global packing machine market is projected to exceed $50 billion by 2025, with a compound annual growth rate (CAGR) of over 5.5%. This growth is largely attributed to advancements in technology that enhance efficiency, reduce labor costs, and improve precision in packaging processes.

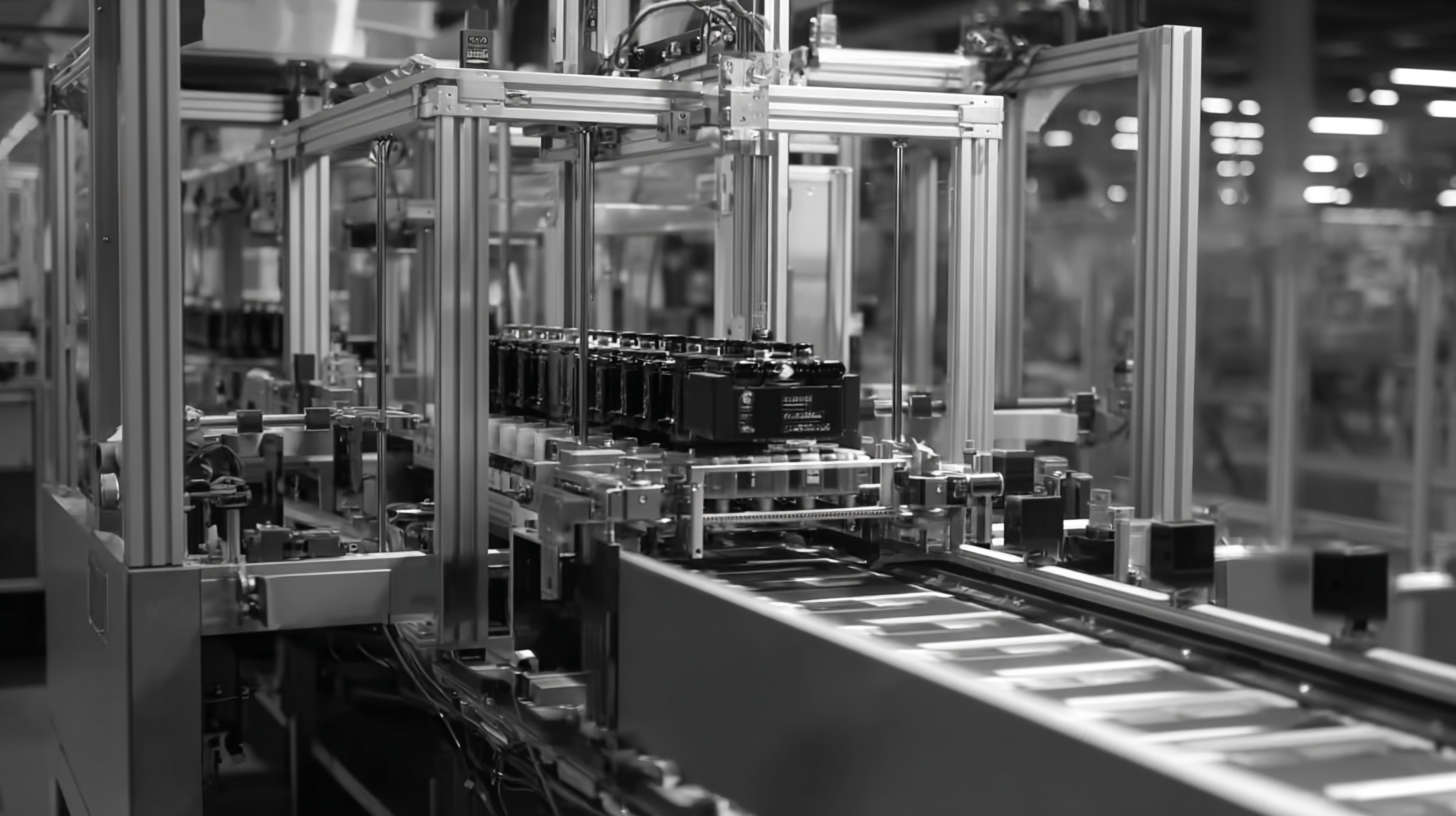

The integration of smart automation, including robotics and artificial intelligence, is revolutionizing the operational capabilities of packing machines, enabling companies to achieve higher productivity levels while maintaining adaptability in response to fluctuating consumer demands. As we delve into the implications of these technological advancements, it becomes essential to understand how automation is not only transforming the packing machine industry but also affecting the broader supply chain dynamics, positioning businesses to thrive in an increasingly competitive market.

The integration of smart automation, including robotics and artificial intelligence, is revolutionizing the operational capabilities of packing machines, enabling companies to achieve higher productivity levels while maintaining adaptability in response to fluctuating consumer demands. As we delve into the implications of these technological advancements, it becomes essential to understand how automation is not only transforming the packing machine industry but also affecting the broader supply chain dynamics, positioning businesses to thrive in an increasingly competitive market.

The role of automation in modern packing machines has transformed the packaging industry by enhancing efficiency, accuracy, and flexibility. Automated packing machines are designed to streamline the entire packaging process, significantly reducing the time it takes to prepare products for shipment. With advanced robotics and artificial intelligence integrated into these machines, tasks such as filling, sealing, and labeling have become faster and more reliable. This not only minimizes human error but also optimizes resource allocation, allowing companies to focus their labor on more complex tasks that require human oversight.

Furthermore, automation has enabled packing machines to adapt to varying production demands with ease. Modern systems are equipped with programmable features that allow for quick reconfiguration when switching between different product lines. This versatility is crucial for businesses facing fluctuating market conditions, as it allows them to maintain high levels of productivity without sacrificing quality. Overall, automation in packing machines signifies a significant leap in operational capabilities, contributing to improved supply chain efficiency and better customer satisfaction.

| Dimension | Description | Impact (Scale 1-10) | Examples of Automation |

|---|---|---|---|

| Efficiency | Reduction in packing time and increase in output. | 9 | Automated packing lines, robotic arms. |

| Accuracy | Improvement in packing precision and reduction of errors. | 8 | Vision systems, weight sensors. |

| Flexibility | Ability to switch between products quickly. | 7 | Modular packing machines, adjustable settings. |

| Cost Reduction | Lowering labor costs and reducing waste. | 8 | Self-operating systems, efficient material usage. |

| Safety | Enhancement of worker safety by reducing manual handling. | 9 | Protective barriers, emergency stop systems. |

The automation of packing machines is becoming increasingly significant, driven by the need for enhanced efficiency and sustainability in the packaging industry. As companies face challenges such as optimizing costs, improving environmental practices, and ensuring compliance with packaging logistics, advanced technologies are playing a crucial role. Key innovations in automation, such as smart filling, sealing, and labeling machines, greatly enhance productivity and reduce waste, allowing businesses to meet both market demands and regulatory requirements effectively.

Moreover, industries are adopting automation technologies not only to streamline their operations but also to respond to the ever-changing landscape of consumer preferences. The integration of flexible production lines and digital solutions in packaging systems exemplifies this shift, facilitating customized solutions for diverse product categories. With events like the upcoming Shanghai Packaging Expo showcasing these advancements, the industry's focus on fostering innovation through automation highlights the strategic importance of embracing technology to navigate future challenges in packaging.

The rise of automated packing systems has transformed the packaging industry, offering significant advantages over traditional manual processes. According to a report by MarketsandMarkets, the automated packaging market is projected to reach USD 55.4 billion by 2024, driven by the efficiency and precision these systems provide. Unlike manual packing, which is labor-intensive and prone to human error, automated systems ensure consistent quality and speed, increasing overall productivity.

In fact, businesses that have adopted automation report a 20-30% reduction in packaging costs and substantial decreases in material waste.

Tips for maximizing efficiency in automated packing systems include regular maintenance of machinery to minimize downtime and investing in training for staff to effectively operate and troubleshoot equipment. Additionally, integrating smart technologies such as IoT can further enhance tracking and inventory management, leading to streamlined operations. By employing these practices, companies can fully harness the benefits of automation, achieving not only greater accuracy but also a competitive edge in the market.

The implementation of automation in packing machines presents a variety of challenges and considerations that organizations must navigate to achieve successful integration. One significant hurdle is the need for a comprehensive understanding of the existing processes. Without a clear analysis, organizations might struggle to identify which tasks are suitable for automation and how these changes will affect workflow efficiency and employee responsibilities. As noted in various sectors, including hotel management and healthcare, thorough planning and assessment are critical in mitigating risks associated with automation.

Moreover, the advent of tools like Robotic Process Automation (RPA) further complicates the landscape. Organizations face governance challenges, particularly around the financial implications of automating processes. Ensuring compliance while maintaining transparency becomes paramount, and companies must devise strategies to align automation initiatives with regulatory requirements. Addressing security concerns is also vital; automating operations without robust security measures can expose organizations to vulnerabilities, particularly as they integrate advanced technologies. As the industry evolves, organizations must adapt to these challenges while leveraging the benefits of automation to enhance productivity and streamline operations.

This chart illustrates the impact levels of various factors associated with the automation of packing machines. The metrics range from cost reduction to labor impact, providing insights into the challenges and considerations faced during implementation.

The future of packaging automation is rapidly evolving, driven by advancements in technology and increasing market demands. According to industry projections, the global automated guided vehicle (AGV) market is anticipated to expand significantly, from a valuation of $2.75 billion in 2025 to approximately $5.44 billion by 2032, reflecting a compound annual growth rate (CAGR) of 10.26%. This growth highlights the industry's shift towards automation to enhance operational efficiency, reduce labor costs, and improve overall productivity in packaging processes.

Furthermore, the anti-static packaging market is expected to see substantial development. Trends indicate a rising need for materials like polyethylene (PE) and polypropylene (PP), particularly in end-use sectors such as electronics and aerospace. The focus on functionality—emphasizing static dissipation and static shielding—along with the evolving sales channels, including direct and online sales, is steering innovation within the industry. Events like the collaboration between technology firms at swop 2023 in Shanghai underline the urgency for businesses to adapt and embrace smart packaging and logistics automation solutions to stay competitive in a rapidly changing market landscape.