Call for Price: 0086-15515573212

The packaging industry, particularly the Wrapping Machine For Food sector, is on the cusp of transformative growth, with projections indicating that the global food packaging machinery market will surpass USD 50 billion by 2025, according to recent industry reports. As consumer demand for convenience and sustainability continues to rise, businesses are increasingly adopting advanced wrapping solutions that enhance product preservation and reduce environmental impact. Notably, innovations such as smart wrapping technologies and eco-friendly materials are set to reshape the landscape, offering companies not only cost savings but also a competitive edge in an ever-evolving market. With these trends in mind, it becomes essential for food-related businesses to embrace new wrapping techniques and machinery, ensuring they remain at the forefront of industry advancements while meeting consumer expectations. This blog will explore the future trends for the best wrapping machines in the food market, providing expert tips to help boost your business in the coming years.

The global food wrapping machine market is set to experience substantial growth by 2025, driven by the increasing demand for efficient packaging solutions in the food industry. With the market projected to expand significantly, businesses must stay ahead of the curve by adopting the latest wrapping technologies. The combined rise of ready-to-eat food products, which are expected to grow from $425.39 billion in 2025 to $626.13 billion by 2032, highlights the urgent need for innovative packaging methods that ensure food safety and extend shelf life.

As companies navigate this evolving landscape, they should consider integrating automated wrapping machines that not only enhance production efficiency but also reduce labor costs. The global vacuum packaging market, for instance, is anticipated to grow from $32.91 billion in 2025 to $50.04 billion by 2032, showcasing a clear trend towards packaging that preserves food quality. By investing in advanced wrapping machinery, businesses can boost their operational capabilities, respond to consumer demand for convenience, and position themselves for sustained success in the competitive food market.

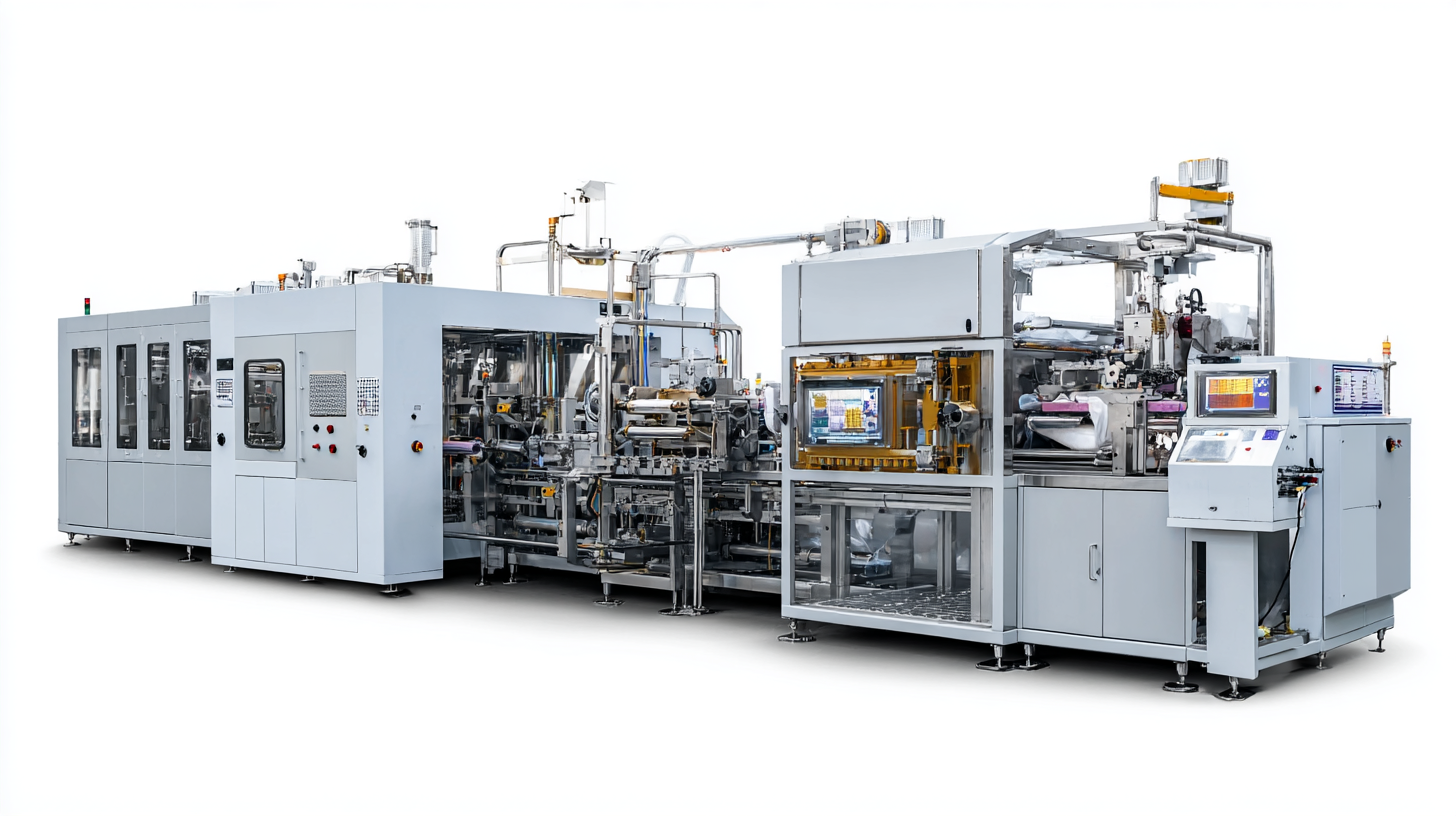

When selecting a top-tier food wrapping machine, key features play a vital role in enhancing operational efficiency and product preservation. According to a recent report from Grand View Research, the global food packaging machinery market is anticipated to reach $50.7 billion by 2025, underscoring the increasing demand for advanced wrapping technologies. A crucial feature buyers should consider is the machine’s speed and output capacity; high-performance models can wrap thousands of products per hour, significantly increasing throughput and reducing labor costs.

Moreover, versatility is another essential characteristic of modern food wrapping machines. With the growing trend towards eco-friendly packaging, machines that can accommodate various materials, including biodegradable films, are becoming indispensable. Research by Research and Markets highlights that the adoption of sustainable packaging solutions could grow by 30% annually through 2025. Additionally, user-friendly interfaces and automation capabilities are vital, allowing for seamless operation and minimal training time for staff. Investing in machines that incorporate advanced technology like IoT integration enables real-time monitoring and maintenance, further optimizing productivity and reducing downtime.

In the rapidly evolving food industry, emerging technologies in food wrapping are playing a pivotal role in enhancing efficiency and meeting consumer demands. As we look toward 2025, innovations such as biodegradable materials, smart packaging, and automated wrapping systems are set to revolutionize how food is packaged.

Biodegradable films made from plant-based materials are not only eco-friendly but also help brands appeal to the growing segment of environmentally conscious consumers. These advancements in materials technology offer businesses a way to reduce their carbon footprint while still providing high-quality packaging solutions.

Biodegradable films made from plant-based materials are not only eco-friendly but also help brands appeal to the growing segment of environmentally conscious consumers. These advancements in materials technology offer businesses a way to reduce their carbon footprint while still providing high-quality packaging solutions.

Additionally, smart packaging is proving to be a game-changer in the food wrapping sector. This technology incorporates sensors that can monitor freshness and provide real-time information to both consumers and retailers. For instance, a package equipped with time-temperature indicators can alert customers if the product has been compromised, ensuring food safety and reducing waste.

Furthermore, automated wrapping systems are enabling food manufacturers to streamline their production processes, minimizing labor costs and improving speed without sacrificing quality. As these innovations continue to flourish, businesses that adopt these technologies will not only enhance their operational efficiency but also position themselves as leaders in the competitive food market.

The integration of automation in wrapping machines is revolutionizing the food industry by enhancing food safety standards. With increased efficiency and precision, automated wrapping systems significantly reduce the risk of human error during the packaging process. These machines not only streamline operations but also maintain strict hygiene protocols, minimizing contamination risks associated with manual handling. As a result, consumers can have greater confidence in the safety of packaged food products.

The integration of automation in wrapping machines is revolutionizing the food industry by enhancing food safety standards. With increased efficiency and precision, automated wrapping systems significantly reduce the risk of human error during the packaging process. These machines not only streamline operations but also maintain strict hygiene protocols, minimizing contamination risks associated with manual handling. As a result, consumers can have greater confidence in the safety of packaged food products.

Furthermore, automation in wrapping machines allows for real-time monitoring and adjustments, ensuring that the packaging process adheres to the necessary safety regulations. Advanced technologies such as sensors and predictive analytics can detect potential issues, enabling businesses to respond proactively before any safety breaches occur. As we move towards 2025, embracing these innovative wrapping solutions will be essential for food companies aiming to enhance their product integrity while simultaneously boosting operational efficiency. The shift towards automation is not just a trend; it's a vital component in the future landscape of food safety management.

Investing in food wrapping solutions is a critical aspect for businesses aiming to enhance their operational efficiency and maximize returns. One of the foremost expert tips is to select a wrapping machine that aligns with your specific food products. Different items, such as delicate pastries or robust meats, require tailored solutions to ensure preservation and aesthetic appeal. By investing in versatile machines that offer adjustable features, businesses can pivot to changing needs, thereby reducing waste and increasing profitability.

Additionally, consider integrating automation into your wrapping processes. Automated wrapping machines can significantly reduce labor costs and increase output, allowing for faster production times without compromising quality. Training your staff to efficiently operate these machines can further optimize the wrapping process, ensuring a seamless flow of operations. Leveraging technology not only maximizes efficiency but also enhances return on investment by providing consistency and reducing the likelihood of errors during the wrapping process. Ultimately, being strategic about equipment choices and operational practices is key to thriving in the competitive food market landscape.