Call for Price: 0086-15515573212

The automatic packing machine industry is experiencing a remarkable transformation, driven by advancements in technology and increasing demand for efficiency in manufacturing and logistics. According to a recent market analysis, the global automatic packing machine market is projected to reach $6.1 billion by 2025, growing at a CAGR of 5.4% from 2020. This growth is fueled by the rising need for automation in various sectors, including food and beverage, pharmaceuticals, and consumer goods. The benefits of implementing advanced automatic packing machines are manifold, providing enhanced speed, reduced labor costs, and improved product integrity. As industries evolve to meet consumer demands for quick and reliable service, understanding the features and advantages of these cutting-edge machines becomes critical for businesses aiming to maintain a competitive edge in the market.

When considering an automatic packing machine, several key features can significantly enhance your packaging efficiency and overall productivity. First and foremost, speed is a critical factor. A machine that can process a higher number of packages per minute can drastically reduce operational time and increase throughput. Look for models equipped with programmable settings that allow you to adjust speeds based on the product being packed, ensuring versatility for different items.

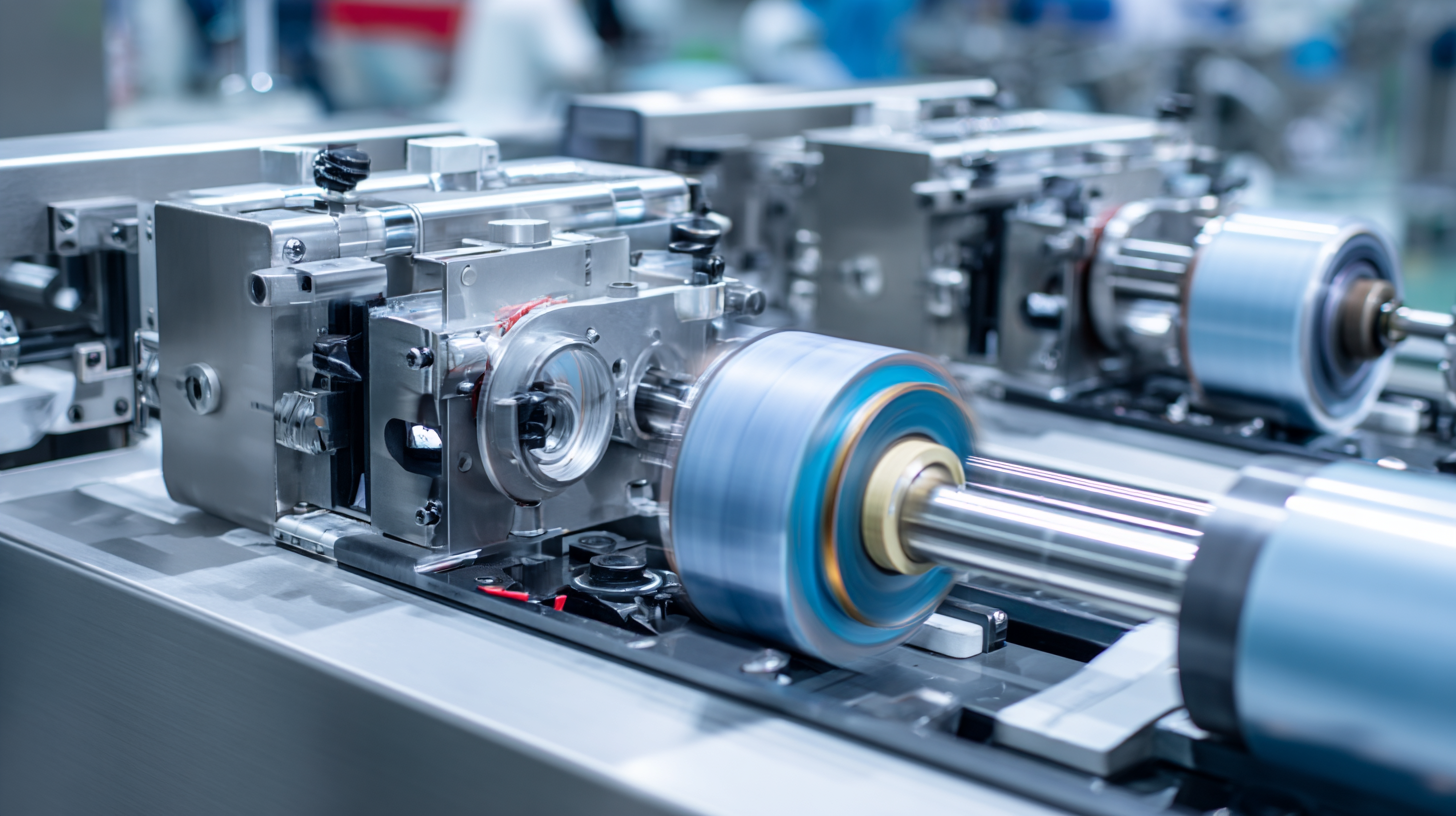

Another essential feature to consider is the machine's adaptability to various packaging materials. The best automatic packing machines can handle a range of materials, such as plastic, cardboard, and foil, allowing for flexibility in your packaging options. Additionally, reliable sealing mechanisms ensure that packages are securely closed, minimizing the risk of product damage during transit. Lastly, user-friendly interfaces and advanced monitoring systems can simplify operation, making it easier for staff to manage the machine and maintain consistency in packaging quality.

Automatic packing machines have revolutionized the way modern industries handle packaging tasks. One of the main advantages of these machines is their efficiency. Unlike manual packing processes, automatic machines can operate continuously at high speeds, significantly increasing productivity while reducing labor costs. This allows companies to meet high demand without compromising on quality, boosting overall operational efficiency.

Another notable benefit is the consistency and precision they offer. Automatic packing machines are designed to deliver uniform sealing and packing, minimizing errors that can occur with manual labor. This consistency not only enhances the aesthetic appeal of the products but also assures customers of the quality they can expect. Moreover, these machines often come with advanced technology, including sensor systems and programmable controls, allowing for flexibility in packaging various product sizes and types, catering to the diverse needs of the market. As industries continue to evolve, the integration of automatic packing machines fosters innovation and improved standards in packaging practices.

Automatic packing machines are essential for various industries, from food and beverage to pharmaceuticals. They significantly enhance productivity and efficiency, with reports indicating that the global automatic packaging machinery market is expected to reach approximately $60 billion by 2026, growing at a CAGR of over 5% from 2021. This growth is driven by the increasing demand for packaged products and the need for businesses to streamline their operations.

There are several types of automatic packing machines, each tailored for specific applications. For instance, vertical form-fill-seal (VFFS) machines are widely used in the food industry for packaging snacks, grains, and liquids, thanks to their ability to operate at high speeds and efficiently handle various pouch styles. Another popular option is the horizontal form-fill-seal (HFFS) machine, which is ideal for packaging products like bars and wraps, providing a robust package that ensures product quality and freshness. According to a recent study by PMMI, nearly 60% of manufacturers reported an increase in production efficiency after integrating automatic packing technologies, underscoring their critical role in maintaining competitiveness in today’s market.

When selecting the best automatic packing machine, several factors play a crucial role. Firstly, the type of product being packaged is paramount. For instance, according to a report by Research and Markets, the global packaging machinery market is expected to grow to $52 billion by 2024, primarily driven by the demand for customized packaging solutions. This indicates that packaging machines must be adaptable, able to handle diverse sizes, shapes, and materials to meet varying industry needs.

Another vital aspect is the machine's speed and efficiency. A study conducted by the Packaging Machinery Manufacturers Institute (PMMI) revealed that companies that upgraded to high-speed packing machines saw productivity increases of up to 30%. Such enhancements not only reduce labor costs but also minimize the time products spend in the packing process, making reliability a key factor when choosing a machine. Additionally, considering the machine's automation features, such as integration with existing software systems for inventory management, can further influence operational efficiency, ensuring enterprises stay competitive in a rapidly evolving market.

The cost-effectiveness of automatic packing machines plays a crucial role in modern industrial operations, particularly in an increasingly competitive market. These machines significantly reduce labor costs by automating repetitive tasks that would otherwise require extensive human resources. Businesses often face immense pressure to enhance efficiency and output, and incorporating automatic packing solutions can lead to substantial savings in both time and costs over the long term.

Moreover, advancements in automation technology, including the rise of intelligent robotics, offer manufacturers the ability to design and implement more efficient packing processes. The integration of smart systems allows for optimized resource allocation and streamlined workflow, ultimately driving business growth.

As the market for packaging solutions continues to expand, understanding the unique features of top-tier automatic packing machines can help businesses leverage these innovations, ensuring they remain competitive while maximizing profitability in their operations.