Call for Price: 0086-15515573212

The evolution of box machine technology has significantly transformed the landscape of modern manufacturing, playing a crucial role in enhancing production efficiency and product quality. As industries continue to demand faster and more reliable solutions for packaging and handling goods, box machines have emerged as a key technological advancement. This introduction aims to explore the various types of box machines and their development over time, highlighting how these machines have adapted to meet the changing needs of manufacturers. By understanding the mechanisms behind box machine technology and its historical progression, we can better appreciate its impact on manufacturing processes, efficiency, and sustainability in today’s competitive market. In particular, the integration of automation and smart technology into box machines represents a leap forward, thereby redefining traditional manufacturing standards and practices.

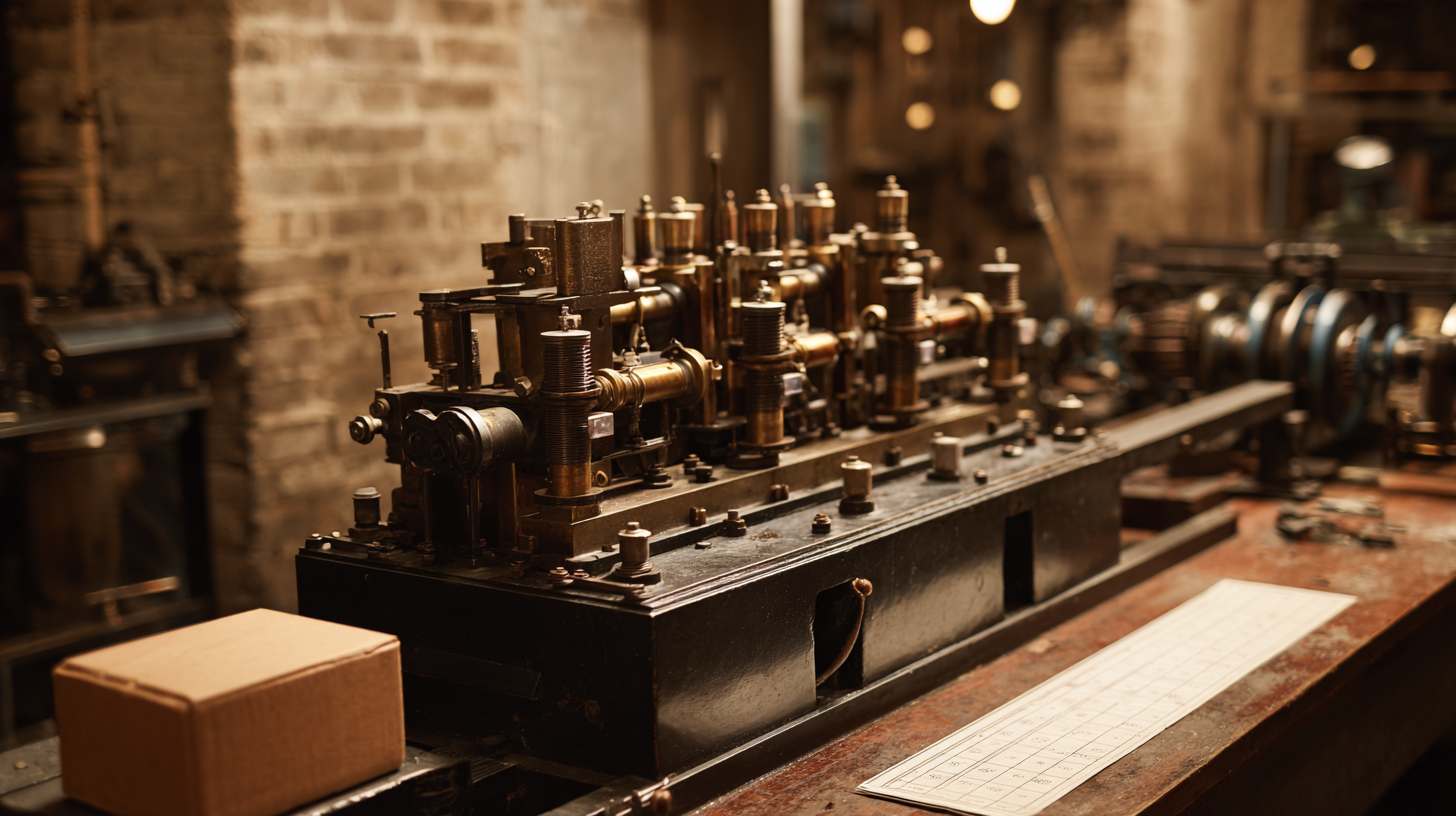

The historical development of box machine technology has significantly influenced the manufacturing landscape. Initially, the advent of basic mechanical systems in the early 20th century allowed for increased production efficiency. According to the International Journal of Manufacturing Technology and Management, the implementation of box machines led to a 30% reduction in manual labor during the 1950s, enabling manufacturers to scale operations rapidly. These machines provided consistent specifications that were previously challenging with manual processes, setting the foundation for modern automation techniques.

As technology progressed, computer numerical control (CNC) systems emerged in the 1970s, revolutionizing box machine capabilities. A report by Market Research Future indicates that the global CNC machine market was valued at approximately $70 billion in 2022 and is projected to reach over $100 billion by 2030. This exponential growth is partly attributed to advances in box machines, which now boast precision, efficiency, and versatility. The integration of smart technology and IoT solutions further enhances manufacturing processes, allowing for real-time monitoring and optimization, ultimately reshaping the industry’s approach to production and quality control.

| Era | Technology Advancement | Impact on Manufacturing | Notable Features |

|---|---|---|---|

| 1800s | Introduction of Mechanical Box Making Machines | Increased production speed and efficiency | Manual operation, basic automation |

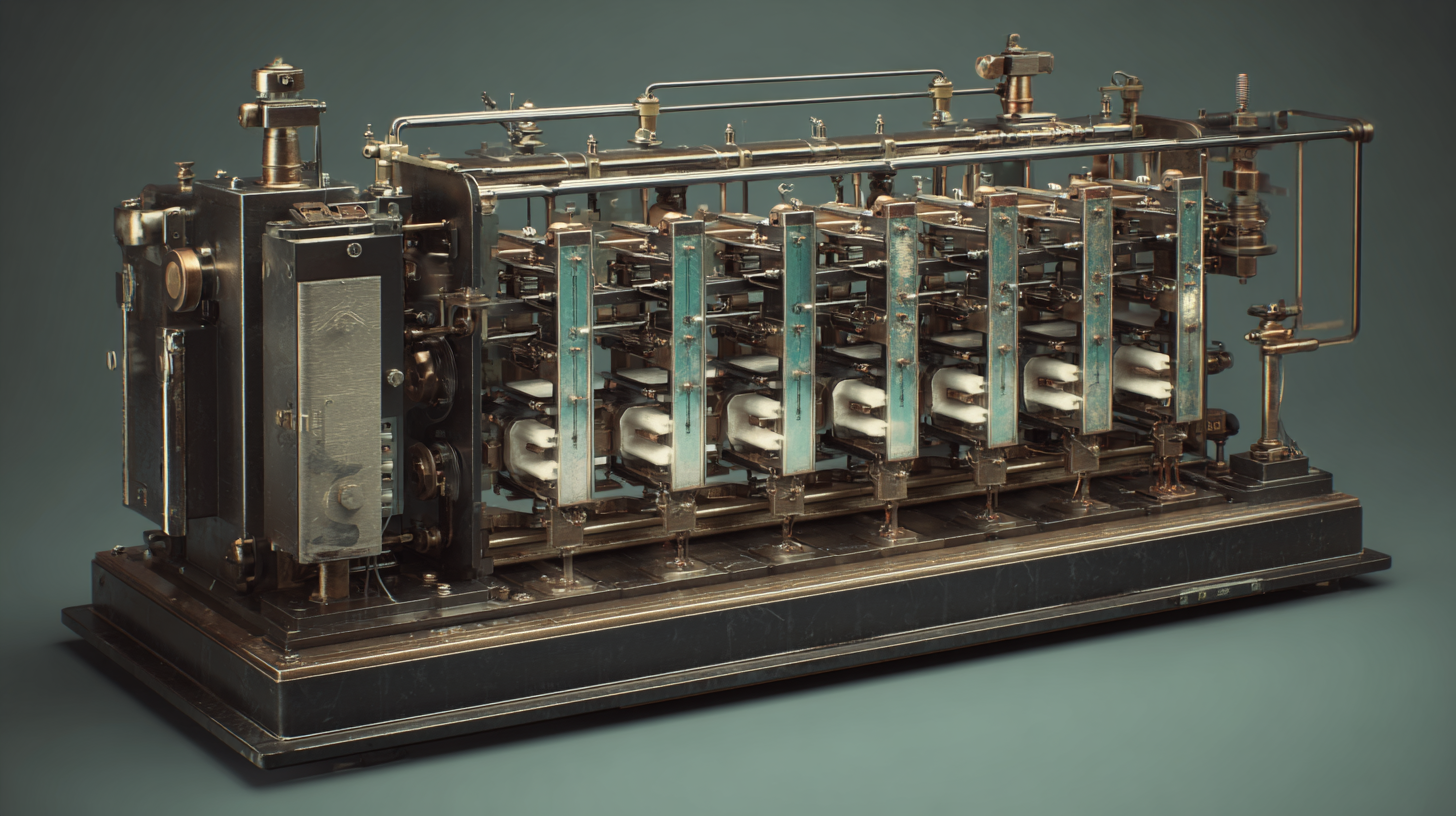

| 1950s | Electromechanical Systems | Enhanced precision and reduced labor costs | Introduction of electric motors, semi-automatic operation |

| 1980s | Computer Numerical Control (CNC) | Significantly improved accuracy and versatility | Automated programming, enhanced design capabilities |

| 2000s | Integration of Robotics and AI | Further automation and customization of production | Smart systems, real-time monitoring |

| 2020s | Advanced IoT Integration | Maximized efficiency and enhanced data analytics | Interconnectivity, predictive maintenance |

The automotive transmission market has witnessed significant evolution, particularly with advancements in box machine technology. From manual transmissions (MT) to automatic variants (AT) and continuously variable transmissions (CVT), manufacturers are embracing innovations that enhance efficiency and performance. Industry reports indicate that the global automotive transmission market is projected to grow significantly, with an estimated value of over $100 billion by 2025, driven largely by the demand for advanced transmission systems.

Innovations such as intelligent manual transmissions (IMT) and automated manual transmissions (AMT) are reshaping the landscape of vehicle performance. By integrating automation into traditional manual designs, these technologies aim to provide the driver with greater control while reducing the physical demands often associated with manual shifting. According to recent market analysis, IMTs are expected to capture a substantial share of the market, reflecting a growing consumer preference for vehicles that offer both efficiency and ease of use. As emissions regulations continue to tighten globally, improvements in transmission technologies will be crucial in meeting both performance goals and environmental standards.

The integration of box machine technology has profoundly influenced production efficiency in modern manufacturing. With the continuous advancement of corrugated box making machines, manufacturers are witnessing a remarkable enhancement in operational productivity. The global market for these machines is projected to grow significantly, with estimates indicating an increase from $0.95 billion in 2025 to $1.36 billion by 2032, showcasing a compound annual growth rate (CAGR) of 5.2%. This growth reflects the increasing demand for efficient packaging solutions that meet the evolving needs of various industries.

Quantitative assessments illustrate how the modernization of box machines directly impacts production processes. Utilizing methodologies such as Life Cycle Assessment (LCA) allows manufacturers to evaluate the sustainability of box machine operations, enabling them to make data-driven decisions that enhance efficiency. As more companies adopt these quantitative methods, the ability to optimize production lines and reduce waste becomes increasingly attainable, driving sustainability while promoting economic growth. The ongoing evolution of box machine technology paves the way for a more efficient and sustainable manufacturing landscape.

Box machines have become pivotal in advancing sustainable manufacturing practices.

By automating the process of packaging and material handling, these machines contribute significantly to reducing waste and enhancing efficiency. This efficiency is crucial not only for lowering production costs but also for minimizing the environmental impact associated with excessive resource consumption. The compact design and optimized operation of modern box machines allow manufacturers to use fewer materials while ensuring the integrity and protection of the products.

Furthermore, the integration of smart technologies into box machines facilitates real-time tracking and data analysis, enabling manufacturers to optimize their supply chains.

This innovation allows companies to monitor their resource usage closely, identify areas for improvement, and implement more eco-friendly practices. As a result, firms can make informed decisions that lead to reduced carbon footprints and improved sustainability metrics.

In essence, the evolution of box machine technology is closely linked to the industry's ability to embrace sustainability, making it an essential component of modern manufacturing strategies.

The integration of Artificial Intelligence (AI) and the Internet of Things (IoT) in box machine technology is poised to revolutionize modern manufacturing. According to a report by MarketsandMarkets, the global AI in manufacturing market is expected to grow from $1.1 billion in 2020 to $16.7 billion by 2026, at a CAGR of 57.2%. This explosive growth highlights the increasing importance of smart technologies in enhancing operational efficiency and decision-making processes within the sector. Box machines, equipped with AI capabilities, can analyze vast amounts of data in real time, optimizing production workflows and reducing waste through predictive maintenance and smarter resource allocation.

Moreover, the IoT's role in box machine technology is crucial for creating interconnected manufacturing environments. A survey by Deloitte found that 79% of manufacturers see IoT as a key driver of productivity improvement. By integrating IoT sensors, box machines can communicate with other devices, allowing for real-time monitoring of production lines and performance metrics. This connectivity not only improves machine uptime but also enables manufacturers to respond swiftly to market changes and consumer demands. As we move forward, the synergy between AI and IoT in box machine technology will redefine manufacturing capabilities, making them more agile, efficient, and responsive to the dynamic nature of global markets.