Call for Price: 0086-15515573212

In recent years, China's commitment to enhancing the quality of industrial machinery, particularly the Cellophane Machine, has positioned the nation as a leader in the global market. According to a report by Research and Markets, the global cellophane market is projected to reach USD 1.55 billion by 2026, growing at a CAGR of 5.2% from 2021. This growing demand underscores the necessity for high-quality cellophane manufacturing technologies, emphasizing the importance of sourcing from reputable suppliers. As manufacturers seek to meet rising consumer standards and sustainability goals, understanding how to identify and collaborate with premium suppliers becomes crucial. The right Cellophane Machine not only influences production efficiency but also impacts the overall product quality, making supplier selection an essential step in the production process.

China has established itself as a powerhouse in the manufacturing of cellophane machines, positioning its technology at the forefront of global markets. Recent reports indicate that the country's production capabilities have grown significantly, with industry outputs increasing by over 15% annually. This rise can be attributed to a combination of innovative manufacturing techniques and a focus on high-quality materials, elevating China's cellophane machines in terms of durability and efficiency.

Additionally, the global demand for eco-friendly packaging solutions has further propelled China's manufacturing sector. According to market analysts, the cellophane machine market is expected to grow to over $1 billion by 2025, driven primarily by sustainable packaging trends. China’s adeptness in adapting to these changes demonstrates its commitment to not only meeting international standards but exceeding them, making it a leader in both production and innovation in the cellophane machinery sector. The country's investments in technology and automation further enhance its competitive edge, positioning Chinese manufacturers as crucial players in the global packaging landscape.

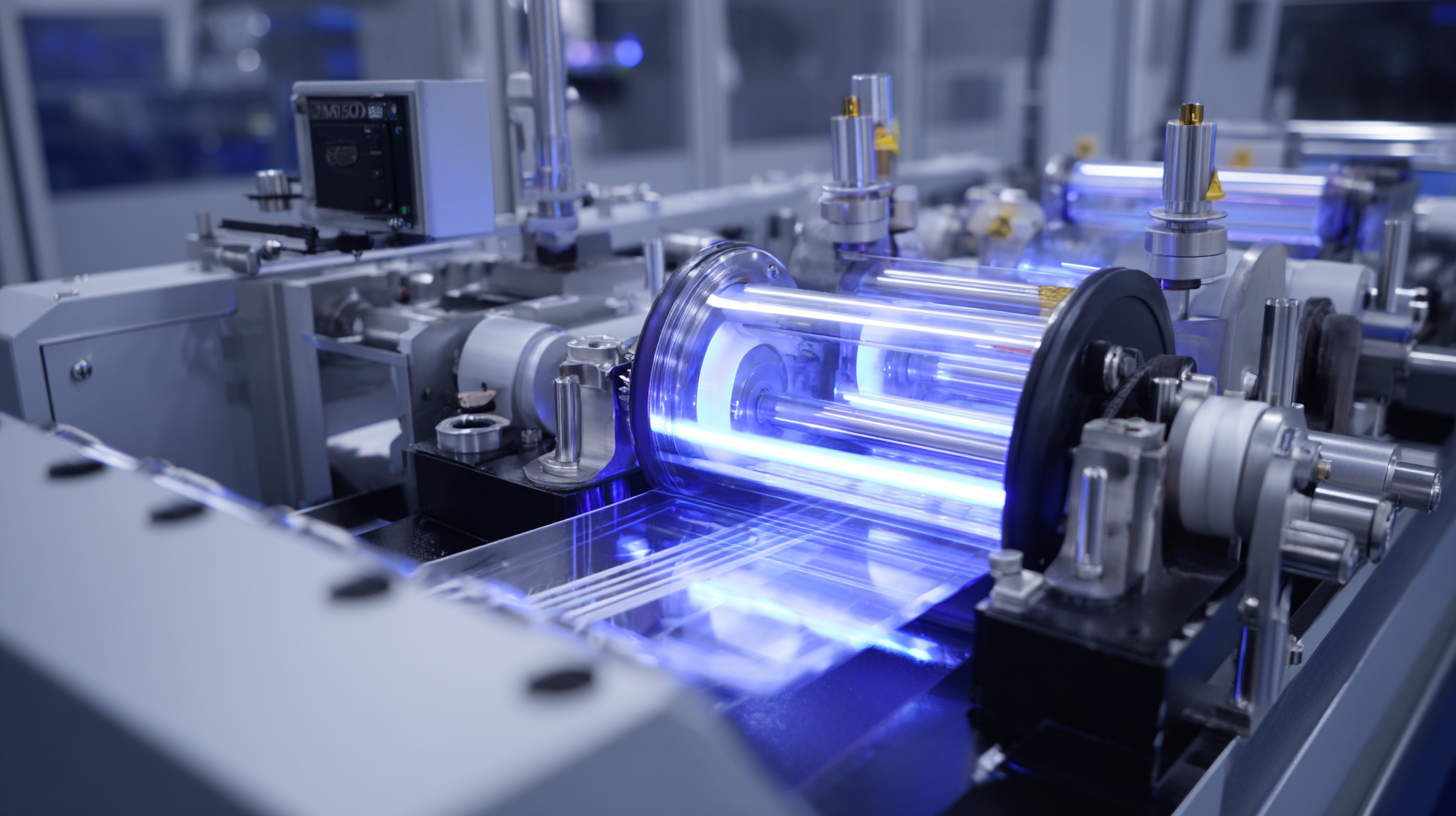

China's commitment to quality in manufacturing has made its cellophane machines stand out in global markets. The key features of high-quality cellophane machines from China include advanced technology, durability, and energy efficiency. These machines are designed to meet international standards, ensuring that they provide reliable performance for various packaging needs.

China's commitment to quality in manufacturing has made its cellophane machines stand out in global markets. The key features of high-quality cellophane machines from China include advanced technology, durability, and energy efficiency. These machines are designed to meet international standards, ensuring that they provide reliable performance for various packaging needs.

One notable aspect is the integration of automation technology, which enhances operational efficiency while reducing labor costs. Manufacturers in China are also focusing on sustainable practices by utilizing eco-friendly materials, aligning with global trends toward sustainability. When considering a cellophane machine, it’s essential to verify the certifications and quality assurances provided by the manufacturer to ensure compliance with international quality standards.

Tips: Always request detailed specifications and operational guidelines from the supplier. Comparing features such as speed, output, and maintenance requirements can aid in selecting the best machine for your production needs. Additionally, look for suppliers with a robust post-sale service system to get support when needed, ensuring long-term operation efficiency.

The global demand for cellophane products continues to witness significant growth, reflecting the evolving trends in the fast-moving consumer goods (FMCG) packaging market. Valued at USD 440 billion in 2022, the FMCG packaging market is projected to exceed USD 770 billion by 2030, with a robust CAGR of 5.9%. This surge is driven by an increasing focus on sustainable and environmentally friendly packaging solutions, where cellophane stands out due to its biodegradable properties and ability to preserve product freshness.

In conjunction with this growth, the cellulose film market, which encompasses cellophane, is also seeing a surge in demand. With applications spanning various sectors, the rise in the biopolymer films market—expected to grow at an 8.4% CAGR through 2028—indicates a strong consumer shift towards eco-friendly alternatives. As industries adapt to meet these preferences, the innovation within cellophane machinery in China positions it at the forefront, ensuring that the best quality products are available to meet the dynamic needs of the packaging market.

In recent years, Chinese manufacturers have made remarkable strides in the production of cellophane machines, showcasing their commitment to quality and cutting-edge technology. With a focus on user-friendly design and efficiency, these machines are increasingly becoming the preferred choice in global markets. Manufacturers are continually integrating advanced technology that enhances production speed while reducing operational costs, ensuring that businesses can meet rising consumer demands without compromising quality.

Tips for selecting the right cellophane machine include assessing the machine's energy efficiency, as this directly impacts your operating costs. Additionally, look for models featuring easy-to-use interfaces and automated functions to streamline your production process. Lastly, consider the availability of customer support and maintenance services from the manufacturer, as ongoing support is crucial for the longevity and reliability of your equipment.

The technological innovations from leading Chinese factories don't stop at performance. Advanced sensors and smart monitoring systems are now embedded in many machines, enabling real-time tracking of production metrics and minimizing the risk of errors. Such innovations not only elevate product quality but also enhance operational flexibility, ensuring manufacturers can adapt swiftly to changing market dynamics.

| Model | Production Capacity (kg/h) | Power Consumption (kW) | Material Type | Efficiency Rating | Price Range (USD) |

|---|---|---|---|---|---|

| C3-2000 | 150 | 15 | Cellophane | A+ | $20,000 - $25,000 |

| C3-3000 | 220 | 20 | Cellophane | A+ | $25,000 - $30,000 |

| C3-4000 | 300 | 25 | Cellophane | A | $30,000 - $35,000 |

| C3-5000 | 400 | 30 | Cellophane | A | $35,000 - $40,000 |

The global packaging industry has seen a significant shift with the rise of Chinese cellophane machines, which are now at the forefront of innovation and quality. A comparative analysis reveals how these machines stack up against their global competitors. Chinese manufacturers have not only focused on technological advancements but also on producing machines that enhance efficiency and reduce waste. This dual focus allows them to provide cost-effective solutions without compromising on quality.

When considering purchasing a cellophane machine, it's crucial to evaluate the features that directly impact your production efficiency. Look for machines equipped with advanced automation capabilities, which can significantly reduce labor costs and improve output rates. Additionally, prioritize models that offer customizable settings to accommodate various product sizes and types, ensuring versatility in your production line.

Another key tip is to assess after-sales support and warranty offered by manufacturers. Reliable customer support can save your business time and money in the long run, especially when it comes to maintenance and troubleshooting. Choosing a machine from a manufacturer with a solid reputation for service can enhance your overall operational reliability and contribute to your business's success in a competitive market.