Call for Price: 0086-15515573212

In the modern packaging industry, efficiency and innovation are paramount, and the "Box Machine" plays a crucial role in streamlining processes. According to a report by Smithers Pira, the global packaging market is expected to reach $1 trillion by 2024, with a significant portion of this growth driven by automated solutions. As businesses strive to enhance productivity and meet consumer demands, the implementation of advanced box machines has become increasingly important. These machines not only produce boxes at a faster rate but also improve the precision of packaging, ensuring that products are securely housed for shipment and storage.

The operation of a box machine utilizes innovative technologies such as robotics and smart automation, allowing manufacturers to reduce labor costs and minimize waste. A study from Market Research Future predicts that the box-making machinery segment will grow at a compound annual growth rate (CAGR) of 4.5% over the next five years. This indicates a robust trend towards increased reliance on box machines in the packaging sector. By optimizing the design and production of packaging materials, companies can enhance their supply chain efficiency, ultimately leading to better customer satisfaction and improved profitability.

In the packaging industry, a box machine is essential for producing corrugated boxes that are widely used for shipping and storage. These machines come in various types, including manual, semi-automatic, and automatic, catering to different production scales and efficiency needs. The manual machines are typically suited for smaller operations, where minimal output is required, while semi-automatic and automatic machines are designed for higher volume production, significantly reducing labor costs and increasing speed.

The market for corrugated box making machines is expanding, with projections showing significant growth from $1.26 billion in 2024 to an estimated $1.88 billion by 2032. This increase is influenced by rising demand for sustainable packaging solutions and automation in the manufacturing process. As manufacturers continue to innovate, the advancements in box machines will likely enhance productivity and cater to the evolving needs of the packaging sector, solidifying their integral role in efficient packaging operations.

| Feature | Description | Functionality |

|---|---|---|

| Speed | Can produce up to 600 boxes per hour | Increases production efficiency |

| Material Compatibility | Works with various materials like cardboard and corrugated paper | Versatile for different packaging needs |

| Automatic vs Manual | Available in both automatic and manual models | Flexibility for various operations |

| Size Adjustability | Can create custom box sizes | Meets specific customer packaging requirements |

| Innovation | Incorporates modern technology such as digital controls | Enhances functionality and ease of use |

A box machine is a critical piece of equipment in the packaging industry, designed to create, fold, and seal boxes for various products. Understanding its key components and their functions helps ensure efficient operation and optimal output.

One essential component is the forming section, where flat sheets of cardboard are transformed into three-dimensional box structures. This area uses creasing and folding mechanisms that precisely shape the material. Following this, the gluing section plays a vital role, applying adhesive to secure the boxes' flaps. The accuracy of this process is crucial for maintaining box integrity.

The closing section typically employs mechanical arms or belts to fold and seal the boxes, readying them for shipping or further processing. To enhance efficiency, many modern box machines are equipped with advanced sensors and automation features.

Tips: Regular maintenance of your box machine can prevent downtime and increase productivity. Always ensure that the adhesive used is compatible with the materials processed to avoid issues during sealing. Additionally, investing in training for operators can optimize machine utilization and reduce errors.

In the packaging industry, box machines play a crucial role in streamlining operations and improving efficiency. These machines come in various types, each designed for specific applications. The most common types include automatic box making machines, semi-automatic machines, and folding box machines. According to a report by Smithers Pira, the global demand for box-making machinery is projected to reach $3.25 billion by 2025, driven by the increasing need for sustainable packaging solutions.

Automatic box making machines are designed to create boxes quickly and with precision. They utilize advanced technology to cut, fold, and glue paperboard into finished boxes. This type of machine is particularly beneficial for high-volume production environments, enabling manufacturers to meet increasing consumer demand while reducing labor costs. Semi-automatic machines, on the other hand, require some manual intervention, making them ideal for smaller businesses that need flexibility without the high capital investment associated with fully automatic systems.

Folding box machines are specifically used for producing boxes that require folding, such as retail packaging for consumer goods. These machines are essential for brands looking to enhance their product presentation on store shelves. According to the Packaging Machinery Manufacturers Institute, the market for folding box machines has seen a growth rate of 4.6% annually, reflecting the rising trend of e-commerce and direct-to-consumer shipping models. Each type of box machine contributes to the packaging landscape by improving speed, efficiency, and packaging quality.

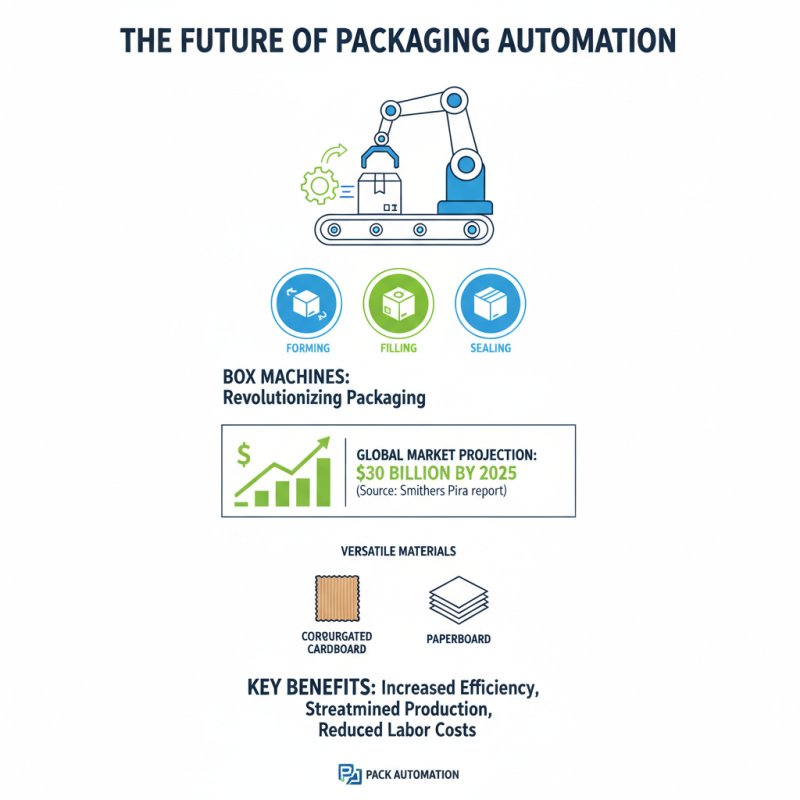

Box machines play a crucial role in the packaging industry by automating the process of forming, filling, and sealing boxes. These machines utilize advanced technology to streamline production lines, significantly increasing efficiency. According to a report by Smithers Pira, the global market for packaging automation is projected to reach $30 billion by 2025, highlighting the demand for such machinery. Box machines are designed to handle various types of box materials, including corrugated cardboard and paperboard, making them versatile for different packaging needs.

The working principle of box machines involves several stages that ensure optimal performance. Initially, flat sheets of material are fed into the machine, which automatically folds and forms them into box shapes through a combination of scoring and creasing techniques. Once the boxes are formed, they are filled with products, and the sealing process commences. The use of adhesive technologies or mechanical seals finalizes the packaging. According to a study from the Association for Packaging and Processing Technologies, the use of box machines can reduce labor costs by up to 30% while improving production speed by 50%, making them an invaluable asset in the packaging sector.

Box machines play a crucial role in modern packaging solutions by streamlining the process of creating and assembling boxes. One of the primary benefits of using box machines is their ability to enhance efficiency. Automated box machines can produce large quantities of boxes in a fraction of the time it would take to do so manually. This efficiency not only speeds up production timelines but also reduces labor costs, allowing businesses to allocate resources more effectively.

Additionally, box machines offer consistency and precision in box production. In industries where uniformity is vital for branding and presentation, these machines ensure that each box is made to exact specifications. This level of accuracy minimizes errors and waste, leading to a more sustainable production process. Furthermore, the adaptability of modern box machines enables them to handle various box styles and sizes, making them suitable for a wide range of products. This versatility is particularly important in today’s fast-paced market, where consumer demands shift rapidly, requiring flexible packaging options.