Call for Price: 0086-15515573212

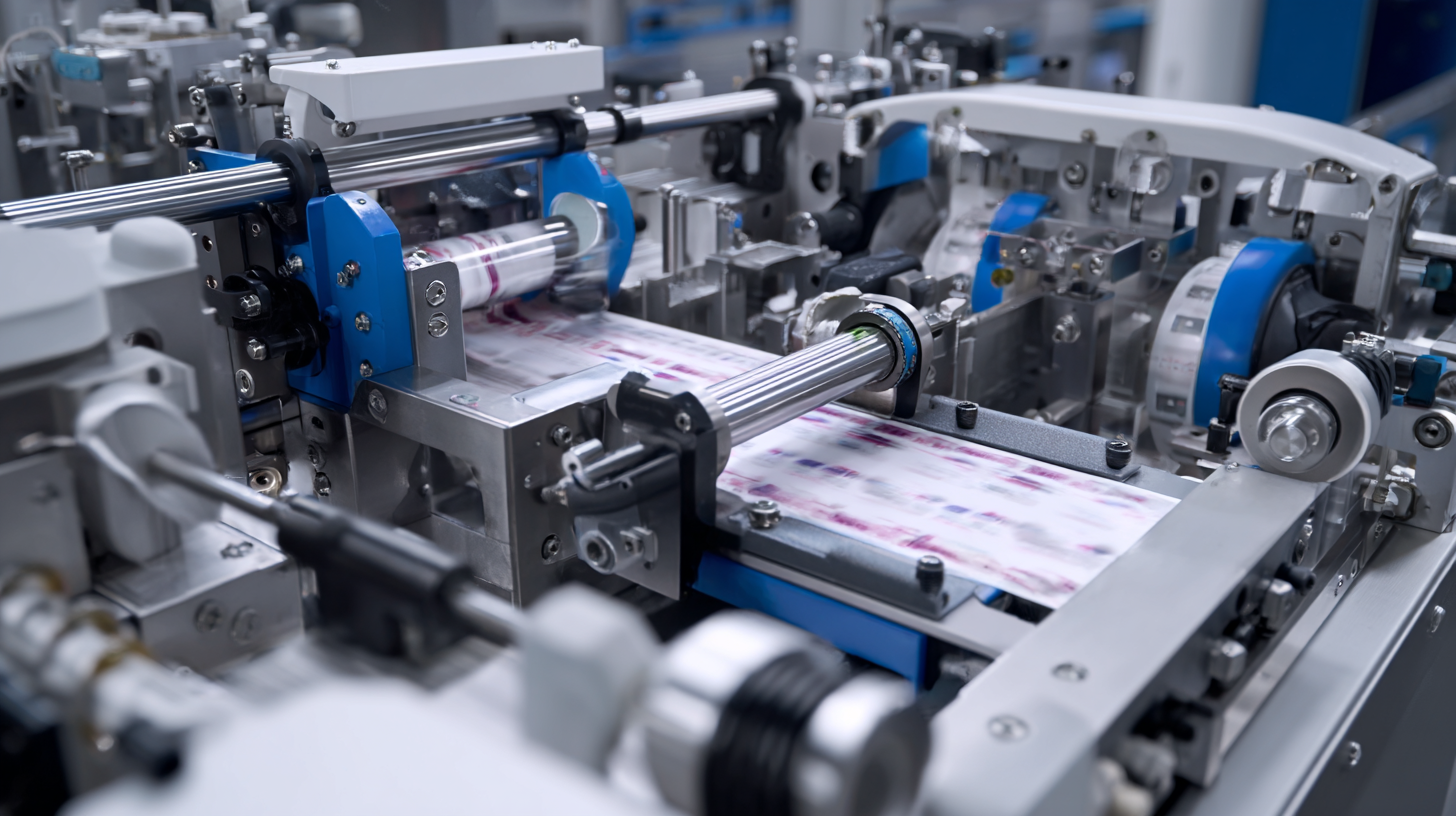

In the rapidly evolving food industry, the significance of efficient and innovative product packaging cannot be overstated. As consumers demand fresher and more convenient options, businesses are increasingly turning to advanced solutions to meet these expectations. One such solution gaining traction is the Overwrapping Machine, a versatile tool designed to enhance the preservation and presentation of food products. This machine not only provides a protective layer against contaminants but also enhances product branding and shelf appeal.

However, selecting the best Overwrapping Machine for specific food applications involves understanding various factors such as material compatibility, output capacity, and compliance with industry standards, including stringent import and export certifications. As we dive into this topic, we'll explore the latest advancements in packaging technology and identify key considerations for choosing an Overwrapping Machine that aligns with the needs of modern food production.

The food packaging industry is witnessing a transformative phase with the advent of high-performance overwrapping machines. These machines are essential for enhancing product longevity and maintaining the quality of food items. According to recent industry reports, the vacuum packaging market is projected to reach USD 42.5 billion by 2027, driven by increasing consumer demand for freshness and convenience. The versatility of overwrapping machines allows them to accommodate various materials, including polyethylene and polypropylene, which are crucial for producing sustainable packaging solutions.

The food packaging industry is witnessing a transformative phase with the advent of high-performance overwrapping machines. These machines are essential for enhancing product longevity and maintaining the quality of food items. According to recent industry reports, the vacuum packaging market is projected to reach USD 42.5 billion by 2027, driven by increasing consumer demand for freshness and convenience. The versatility of overwrapping machines allows them to accommodate various materials, including polyethylene and polypropylene, which are crucial for producing sustainable packaging solutions.

When selecting an overwrapping machine for food applications, consider the key features that enhance operational efficiency. Look for machines equipped with advanced sealing technology to ensure tight seals and prevent contamination. Additionally, energy efficiency is a growing trend, as manufacturers aim to reduce operational costs while being environmentally conscious.

Tips: Always evaluate the compatibility of the machine with different packaging materials to ensure optimal performance. Regular maintenance is essential to extend the lifespan of the machinery and maintain production quality. Finally, investing in machines with automation capabilities can streamline operations and increase productivity significantly.

The food packaging industry is undergoing a remarkable transformation as we approach 2025, driven by technological advancements and shifting consumer expectations. According to a recent report by Smithers Pira, the global food packaging market is projected to reach $459 billion by 2024, reflecting a significant growth trajectory. One of the notable trends shaping this market is the increasing demand for sustainable and eco-friendly packaging solutions. Industry leaders are exploring biodegradable materials and recyclable options to minimize environmental impact, with a particular focus on reducing single-use plastics.

Another exciting trend is the integration of smart technology within packaging processes. The Food and Drug Administration (FDA) has noted an uptick in the implementation of smart labels and tracking systems, which enhance food safety and traceability. This innovation not only provides consumers with crucial product information but also streamlines supply chain management. As more companies adopt intelligent packaging solutions, it is anticipated that these innovations will promote consumer trust and strengthen brand loyalty. Embracing these trends will be essential for food manufacturers looking to remain competitive in this rapidly evolving landscape.

In the food industry, packaging plays a crucial role in preserving product freshness and ensuring consumer safety. Overwrapping machines have emerged as essential tools for achieving optimal packaging efficiency. When evaluating the best overwrapping machines for food applications, several key factors come into play: speed, adaptability, and ease of use. Leading models, such as the XYZ series, offer advanced features like programmable settings and quick-change capabilities, allowing manufacturers to switch between different product sizes with minimal downtime.

Another strong contender is the ABC overwrapping machine, renowned for its ability to handle a variety of materials and its energy-efficient design. This model excels in high-volume environments, providing consistent wrapping quality that enhances shelf appeal while reducing waste. Additionally, user-friendly interfaces and smart technology integration further streamline the production process, making these machines a significant investment for businesses looking to innovate their packaging solutions.

By carefully analyzing these top choices, food manufacturers can make informed decisions that not only optimize their packaging lines but also meet the evolving demands of the market.

In recent years, the food industry has witnessed a significant shift towards overwrapping technology as a solution for enhancing product packaging. A report by Smithers Pira indicates that the global market for overwrapping machines is projected to reach $3.2 billion by 2026, reflecting a compound annual growth rate of 4.5%. This uptick is driven by the need for improved shelf life and protection against environmental factors, which are critical in maintaining the quality of food products.

Real-world case studies illustrate the successful implementation of overwrapping technology. For instance, a leading snack manufacturer adopted an overwrapping machine that increased packaging efficiency by 30% while reducing material costs by approximately 20%. By switching to overwrapping, the company not only enhanced the visual appeal of its products but also extended the shelf life, leading to a 15% increase in sales within the first quarter of adoption. Such tangible benefits highlight the critical role of overwrapping machines in food packaging, pushing companies towards innovation and improved operational workflows.

| Application Area | Machine Type | Speed (packs/min) | Materials Supported | Key Features | Implementation Case Study |

|---|---|---|---|---|---|

| Snack Foods | Automatic Overwrapping Machine | 100 | BOPP, CPP | Adjustable Speed, Touchscreen Control | Increased output by 30% after implementation |

| Dairy Products | Horizontal Flow Wrapper | 80 | PE, PVDC | Multi-lane Packaging, Easy Setup | Reduced spoilage by 20% |

| Confectionery | Vertical Overwrapping Machine | 120 | PVC, OPP | Servo Motor Technology, Washdown Design | Increased flexibility with smaller batch sizes |

| Bakery Items | Semi-Automatic Overwrapper | 50 | Paper, Film | Compact Design, Easy Maintenance | Significantly improved packing speed |

| Frozen Foods | Continuous Motion Overwrapper | 70 | PE, LDPE | Energy Efficient, Low Waste | Reduced packaging waste by 15% |

As the food packaging industry continues to evolve, overwrapping machines are poised to be at the forefront of this transformation by 2025. According to recent market research, the global overwrapping machines market is projected to grow at a CAGR of 5.2%, driven by the increasing demand for efficient packaging solutions that extend shelf life and enhance product presentation. This growth is particularly evident in the food sector, where companies are prioritizing both product freshness and sustainability in their packaging choices.

The advantages of overwrapping machines extend beyond basic functionality; they offer a range of customization options that align with consumer preferences. Reports indicate that over 70% of consumers prefer packaging that minimizes environmental impact while still maintaining product integrity. By implementing advanced overwrapping technologies, food manufacturers can not only comply with these consumer demands but also reduce material waste, with some machines capable of using up to 30% less film compared to traditional wrapping methods. The integration of smart features, such as IoT connectivity, will further enhance operational efficiency and enable real-time monitoring of packaging processes, ensuring that the food industry is ready for the challenges of the future.