Call for Price: 0086-15515573212

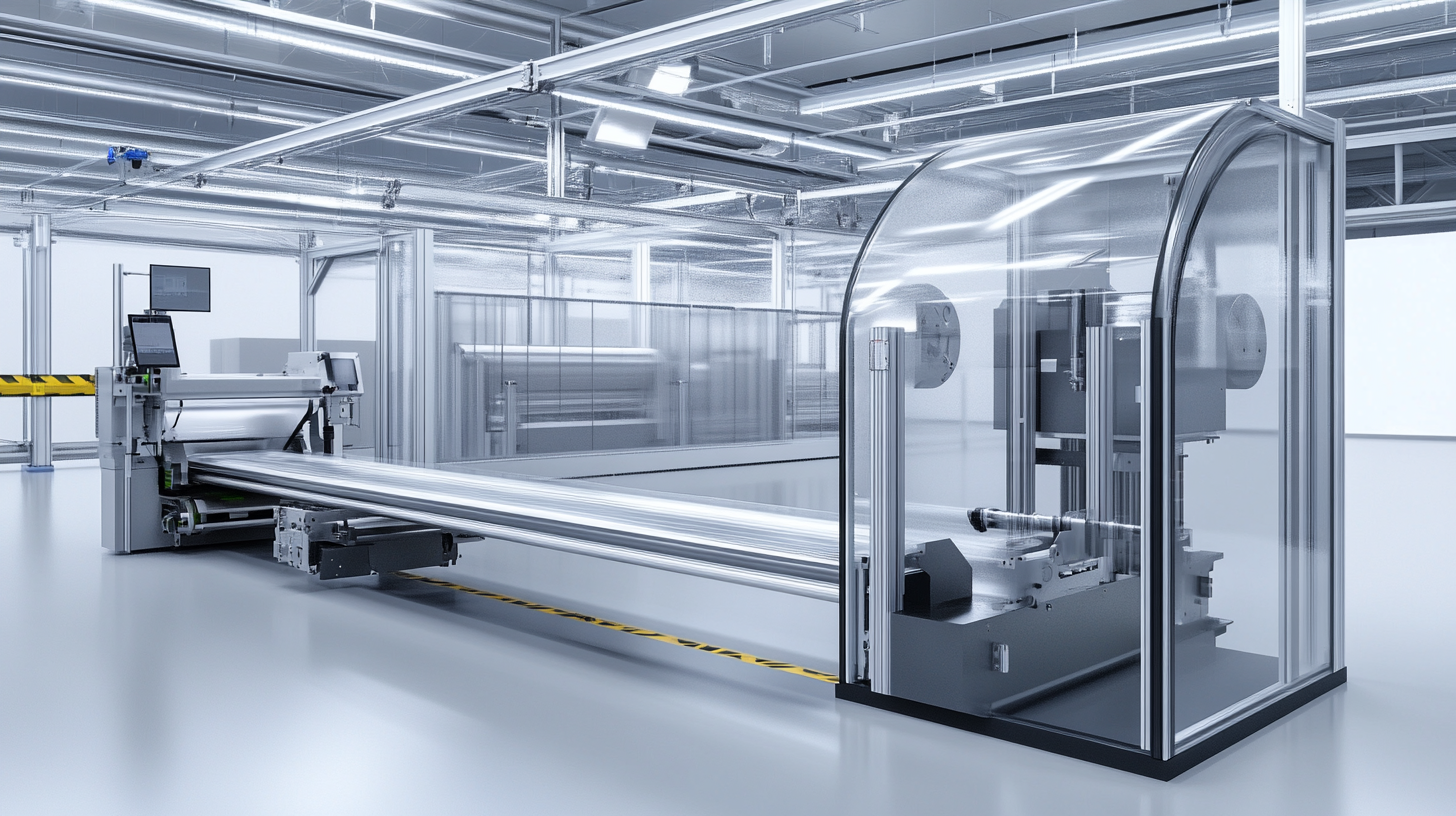

The advent of the Box Wrapping Machine has revolutionized packaging across multiple industries, showcasing innovative applications that enhance efficiency and sustainability. According to a report by Smithers Pira, the global packaging machinery market is projected to reach $45 billion by 2025, driven by technological advancements and the increasing demand for consumer goods.

Box wrapping machines, integral to this growth, optimize the packaging process, reduce material waste, and improve product delivery times.

The versatility of these machines allows them to be employed in various sectors—from e-commerce and food processing to pharmaceuticals—each presenting unique challenges that require tailored solutions.

As we delve into the innovative uses of box wrapping machines, it becomes evident that they are not merely tools, but essential components for maintaining competitive advantage in an evolving market.

The advent of the Box Wrapping Machine has revolutionized packaging across multiple industries, showcasing innovative applications that enhance efficiency and sustainability. According to a report by Smithers Pira, the global packaging machinery market is projected to reach $45 billion by 2025, driven by technological advancements and the increasing demand for consumer goods.

Box wrapping machines, integral to this growth, optimize the packaging process, reduce material waste, and improve product delivery times.

The versatility of these machines allows them to be employed in various sectors—from e-commerce and food processing to pharmaceuticals—each presenting unique challenges that require tailored solutions.

As we delve into the innovative uses of box wrapping machines, it becomes evident that they are not merely tools, but essential components for maintaining competitive advantage in an evolving market.

The rise of e-commerce has revolutionized the packaging landscape, emphasizing the need for innovative box wrapping solutions. According to a report by McKinsey, e-commerce sales are projected to reach $6.3 trillion by 2024, with packaging efficiency becoming a critical factor in supply chain management. As a result, many companies are turning to advanced box wrapping machines that not only enhance the speed of packaging but also ensure perfect protection of goods during transit.

One of the key challenges faced by e-commerce businesses is the sustainability of their packaging. A survey by Statista reveals that 58% of consumers are willing to pay more for sustainable packaging. Innovative box wrapping machines now offer solutions that utilize recyclable materials and minimize waste, thereby addressing both consumer preferences and environmental concerns. Additionally, these machines can accommodate various box sizes and shapes, streamlining the packaging process while reducing the overall operational cost. As the industry continues to evolve, the role of sophisticated box wrapping technology becomes increasingly central to overcoming packaging challenges and meeting consumer expectations.

| Industry | Use Case | Benefits | Challenges Addressed |

|---|---|---|---|

| E-Commerce | Automated Shipment Packaging | Increased efficiency and reduced labor costs | High-volume packaging demands |

| Food & Beverage | Gift Basket Wrapping | Aesthetic appeal and preservation of freshness | Maintaining product integrity |

| Electronics | Custom Packaging for Fragile Items | Protected shipping and enhanced user experience | Reducing damage during transit |

| Cosmetics | Luxury Gift Packaging | Brand differentiation and customer appeal | Standing out in a competitive market |

| Retail | Seasonal Decor Packaging | Enhancing visual merchandising | Attracting customer attention during holidays |

Box wrapping machines have revolutionized packaging processes across various industries, with a significant focus on their role in the retail sector. One of the most impactful benefits of these machines is their ability to reduce material waste, an increasingly critical concern in today's environment. By automating the wrapping process, businesses can optimize material usage, ensuring that only what is necessary is used for packaging products. This not only minimizes excess waste but also leads to cost savings, making operations more sustainable.

Tip: When selecting a box wrapping machine, it’s essential to consider its efficiency in material consumption. Look for machines that offer adjustable settings to accommodate various box sizes, which can help in using just the right amount of wrapping material needed.

Additionally, the integration of advanced technology in box wrapping machines allows for improved precision in packaging. This ensures that products are securely wrapped while eliminating the chances of damage during transit. As a result, retailers can reduce the need for additional packaging materials, further contributing to waste reduction.

Tip: Regularly train staff on best practices for operating box wrapping machines to ensure they maximize efficiency and minimize waste during the wrapping process. This proactive approach can lead to a more streamlined operation and environmentally friendly practices.

The growing threat of theft and damage to products across various industries has necessitated innovative solutions, with box wrapping machines leading the charge. These machines not only enhance the presentation of goods but provide substantial security benefits. For instance, the use of advanced box wrapping techniques can deter theft significantly by making tampering more apparent. Research indicates that a well-secured product is far less likely to be targeted by thieves, particularly in high-risk retail environments.

In a detailed report by industry experts, it was found that approximately 30% of retailers have reported losses due to theft, highlighting the urgent need for effective security measures. For example, the integration of smart wrapping technologies with devices like EAS tags can bolster security further. The Turtle, a multifunctional EAS tag, has been shown to activate pre-alarms when unauthorized movements are detected, adding another layer of defense for high-loss items. Coupled with advanced surveillance methods like those employed in self-checkout areas, the effectiveness of box wrapping machines in safeguarding products cannot be overstated. These technological advancements reflect a shift towards comprehensive security solutions in packaging, making it a crucial consideration for modern businesses aiming to protect their assets.

The following chart illustrates the effectiveness of box wrapping machines in reducing theft and damage across various industries. The data represents the percentage reduction in incidents after implementing box wrapping technology.

Box wrapping machines have revolutionized operations in the food processing industry by optimizing production efficiency. According to a report by Grand View Research, the global food packaging machinery market is expected to reach $45 billion by 2026, driven by an increasing demand for packaged foods. These machines streamline the wrapping process, significantly reducing manual labor and minimizing material waste, which is crucial in a market where efficiency translates directly to profit margins.

In terms of practical applications, many food processing companies have adopted automatic box wrapping machines to enhance their packaging speed and consistency. For instance, a case study from a leading snack manufacturer noted a 30% increase in packaging speed after integrating a box wrapping machine into their workflow. This improvement not only helped them meet rising consumer demand but also improved product freshness by minimizing exposure to air and contaminants during packaging.

Tip: When considering a box wrapping machine, assess your production volume and choose one that allows for easy scalability.

Another notable example comes from a beverage company that replaced its manual wrapping process with an automated solution, resulting in a 50% reduction in labor costs. The precision of these machines also minimizes product damage and enhances brand presentation, making them a vital investment for businesses looking to stay competitive.

Tip: Regularly maintain your wrapping machine to ensure optimal performance and avoid unexpected downtimes, which can disrupt production lines.

In the fast-paced worlds of pharmaceuticals and cosmetics, adhering to compliance standards is paramount. Box wrapping machines play a pivotal role in ensuring that products are packaged correctly, maintaining safety, and adhering to regulatory requirements. These machines not only enhance efficiency but also help in applying tamper-evident seals and secure closures that are essential for consumer protection. The automation of wrapping processes reduces the potential for human error, ensuring that each package meets the stringent safety standards prevalent in the industry.

Moreover, as consumer awareness towards product safety continues to rise, the packaging itself has become a key marketing tool. Businesses are leveraging advanced box wrapping machines that allow for customizable designs and materials, aligning with brand identity while still prioritizing compliance. These innovations enable companies to meet regulatory guidelines without sacrificing visual appeal. Ultimately, the integration of modern box wrapping technology is revolutionizing how pharmaceuticals and cosmetics are packaged, ensuring that they not only comply with industry standards but also resonate with consumers on a deeper level.