Call for Price: 0086-15515573212

An Automatic Wrapping Machine is a sophisticated piece of equipment designed to streamline the packaging process across various industries. With the rapid advancement of technology, these machines have become essential for businesses aiming to enhance efficiency and productivity in their operations. By automating the wrapping process, companies can minimize labor costs, reduce material waste, and achieve a more consistent packaging quality. This innovation not only saves time but also allows for the accommodation of higher production rates.

In this article, we will delve into the intricate workings of the Automatic Wrapping Machine, exploring its components, functionality, and the various types available on the market. Understanding how these machines operate provides valuable insights for businesses looking to invest in packaging solutions that can transform their operations. From horizontal and vertical wrapping machines to customized systems tailored to specific needs, the variety of options available enhances versatility and meets the diverse demands of different sectors. As we uncover the mechanisms behind these automatic machines, the benefits they offer can become clearer, reinforcing their significance in modern manufacturing and packaging industries.

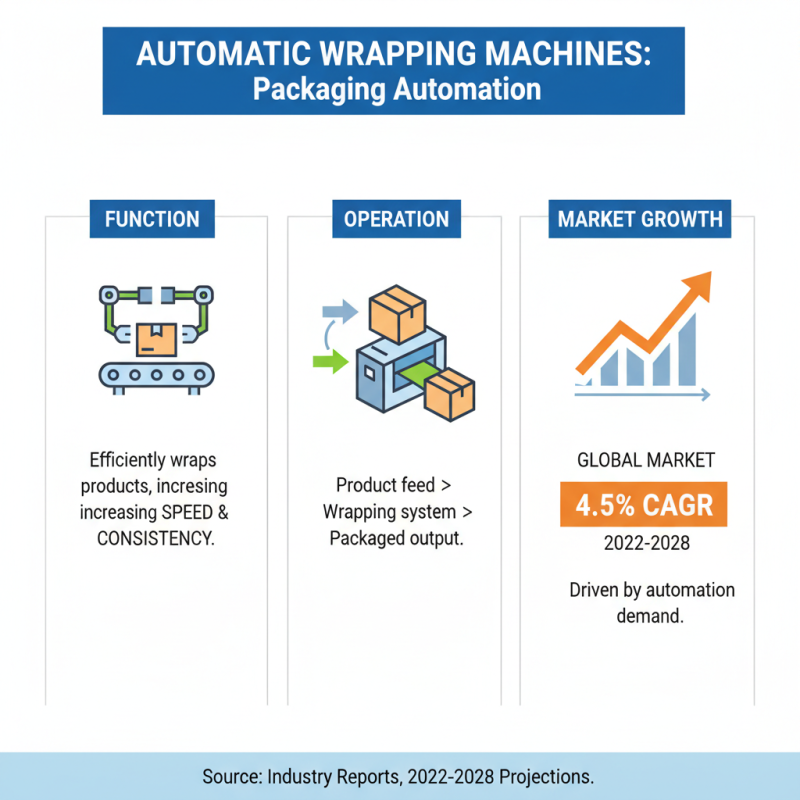

An automatic wrapping machine is a sophisticated piece of equipment designed to efficiently package products in a protective film or material. The primary purpose of such machines is to enhance the speed and accuracy of the wrapping process, which can significantly improve productivity in various industries including food, pharmaceuticals, and consumer goods. By automating the wrapping process, these machines reduce the need for manual labor, minimize the chances of human error, and ensure consistent quality in packaging.

The operation of an automatic wrapping machine typically involves several key steps. First, the product is positioned on a conveyor system, where sensors detect its dimensions and position. The machine then depends on advanced mechanisms to dispense the wrapping material, often using heat seals or adhesive solutions to secure the package tightly. Additionally, automatic wrapping machines can be programmed to handle various product shapes and sizes, making them versatile solutions for manufacturers looking to streamline their packaging processes. This ensures that products are not only well-protected during transport and storage but also presented attractively for consumers.

An automatic wrapping machine is a sophisticated piece of equipment designed to package products in a secure and efficient manner. The primary components of these machines play crucial roles in ensuring the wrapping process is smooth and reliable. Key elements include the conveyor belt, wrapping arm, film dispenser, and control system.

The conveyor belt is responsible for transporting products into the wrapping area at a controlled speed, ensuring consistent flow and minimizing the risk of jams. Once the products reach the wrapping arm, the mechanism takes over to wrap the product securely with minimal human intervention. The film dispenser provides the protective wrapping material, enabling the machine to adjust the amount of film used based on the size and type of the product. Additionally, the control system oversees the entire operation, allowing operators to adjust settings, speed, and wrapping specifications, which enhances the efficiency and adaptability of the machine for different packaging needs.

Overall, the seamless integration of these components allows automatic wrapping machines to operate smoothly, providing a reliable solution for high-speed packaging in various industries.

An automatic wrapping machine is a sophisticated piece of equipment designed to efficiently wrap products in various industries, enhancing both speed and consistency. The operation of these machines typically begins with feeding the product into the wrapping system. According to industry reports, the global market for automatic wrapping machines is expected to grow significantly, with a projected annual growth rate of 4.5% from 2022 to 2028, underscoring the increasing demand for automation in packaging processes.

Once the product is inserted, a series of mechanical components take over. The machine utilizes conveyor belts to transport the item to the wrapping station, where it is encased in protective materials such as plastic film or paper. Sensors and control systems are integrated to ensure precise alignment and wrapping. After the product is securely wrapped, it undergoes a sealing process, which may involve heat or adhesive, to maintain the integrity of the packaging. As per a recent market analysis, over 60% of manufacturers utilize automatic wrapping machines to enhance productivity, minimize labor costs, and improve packaging quality.

The final stage involves the wrapped product being discharged onto another conveyor for further processing or distribution. This streamlined approach not only reduces human error but also accelerates the overall production line. Reports indicate that automating the wrapping process can lead to efficiency gains of up to 25%, allowing companies to meet growing consumer demands more adeptly while maintaining competitive advantage in the packaging market.

Automatic wrapping machines are essential equipment in various industries, streamlining packaging processes and enhancing efficiency. There are several types of automatic wrapping machines available in the market, each designed to cater to different packaging needs. The most common types include horizontal wrappers, vertical wrappers, and stretch wrappers.

Horizontal wrappers are typically used for products that require tight and secure packaging, often seen in food and pharmaceuticals. According to a report from Global Market Insights, the horizontal wrapping machine market is expected to witness significant growth, driven by increasing demand for packaged goods.

Vertical wrappers, on the other hand, are ideal for flexible packaging and are commonly used in the snack and cereal industries. These machines operate by forming a tube from a flat film reel, filling it with the product, and then sealing it. The rise in e-commerce and online food delivery services has further boosted the demand for vertical wrapping solutions, as companies seek to improve packaging efficiency while maintaining product integrity.

Additionally, stretch wrappers are employed to wrap products on pallets, offering security during transportation. Reports from Research and Markets indicate that the stretch wrapping machine segment is projected to grow at a CAGR of over 4% in the coming years, reflecting the ongoing shift towards automated packaging systems in supply chain operations.

As industries continue to evolve, the development of advanced wrapping technologies is also on the rise. Newer models incorporate features such as programmable logic controllers (PLCs) and automated film feed systems, enhancing user control and operational efficiency. The expansion of automation in packaging, as highlighted in a study by the Packaging Machinery Manufacturers Institute, underscores the crucial role of automatic wrapping machines in meeting the growing demands of modern manufacturing and distribution processes.

Automatic wrapping machines have revolutionized the packaging industry by enhancing efficiency and consistency in packaging processes. One significant advantage of these machines is their ability to increase production speed. According to a recent industry report from MarketsandMarkets, the global automatic packaging market is expected to grow at a CAGR of 4.8%, reaching $50 billion by 2025. This surge is largely driven by the adoption of automated solutions, which facilitate faster operations and reduce manual labor.

Another critical benefit is improved material usage. Automatic wrapping machines can efficiently apply just the right amount of packaging material, minimizing waste. This is particularly vital in today's sustainability-conscious market. A study from the Association for Packaging and Processing Technologies highlights that companies can reduce packaging costs by up to 15% through automation. This not only cuts expenses but also contributes to a greener approach by reducing the carbon footprint associated with excess packaging materials.

*Tips: When selecting an automatic wrapping machine, consider features such as speed settings and adjustable wrapping dimensions to accommodate various product sizes. Additionally, ensure that the machine is compatible with eco-friendly materials to align with sustainable practices.*